Understanding The CNC Milling Process

by Abdul Aziz Mondal Technology Published on: 16 December 2021 Last Updated on: 25 September 2024

Like any traditional CNC machining guide, the milling process employs computerized numerical control commands to drive the cutting tools. Let’s look at the milling process step by step.

Step 1: Design

Computer-aided design (CAD) software helps create a 2D or 3D model of the component. The design is the most crucial part of the process. Designers take exceptional care to ensure that the outline contains specific details. Simultaneously, designers must ensure that they do not excessively complicate the design for the prototype.

Step 2: Rendering The CAD Design Into Code

Machines can read CNC-compatible codes. The next step is to encode the design into CNC-readable code. The CNC compatible codes will maneuver the cutters to guide them to remove materials based on the outline. In this stage, manufacturers can pinpoint any mistakes in the code and make the necessary adjustments.

Engineers can modify the design and produce designs and code for alternative optimal models of the original prototype.

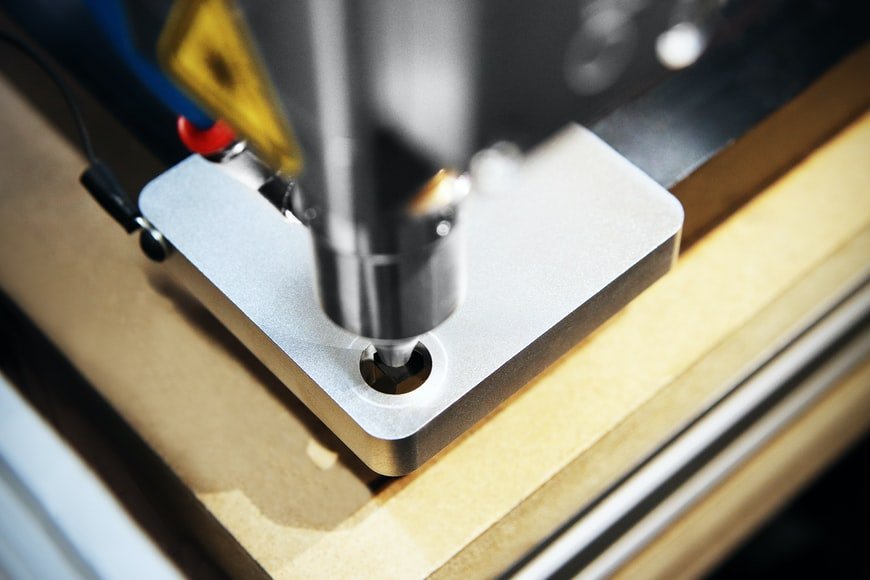

Step 3: Machine Setup

Even though the machining process is fully automatic. But there is still a need for manual interaction. For example, engineers make sure to set the workpiece on the table and ensure that the final product is in coordination with the design.

Once the initial setup is complete, the operator initiates the program to let the machines run the code.

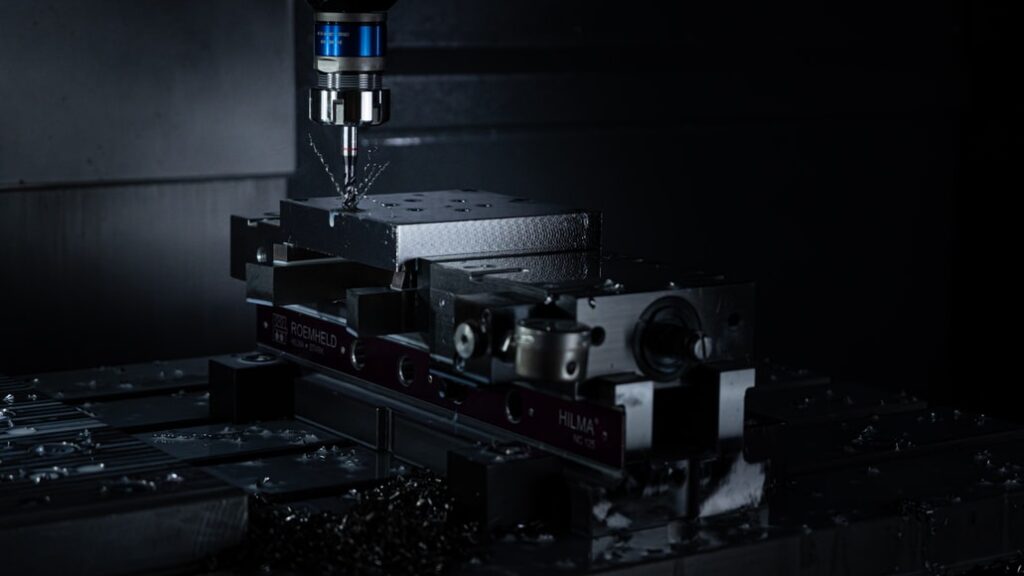

Step 4: Production

Production starts, and this is the final step of the milling process. The cutter or rotating tool makes contact with the selected materials. The machines remove excessive chips or fragments on the piece to produce the final version of the product.

Advantages Of The CNC Milling Process In Comparison To Other Technologies

The CNC milling process is extraordinarily complicated but capable of producing parts with minimum human involvement. Consequently, the milling process develops components and products for almost any industry with zero mistakes and complete perfection.

Next, we look at some of the benefits of the milling process.

Automated and Uninterrupted Production

The milling process can run for hours, days, or even longer based on demands because it is fully automated. Manufacturers can achieve the highest productivity by maintaining efficient production. Businesses can constantly operate automated sequences to ensure the lowest costs.

Optimal Precision

The milling process ensures accuracy and precision that is second to none. The process produces products and components with the highest precision and maximum accuracy. The meticulousness and definition of the products made by the milling process are why the medical and aerospace industry depends on it.

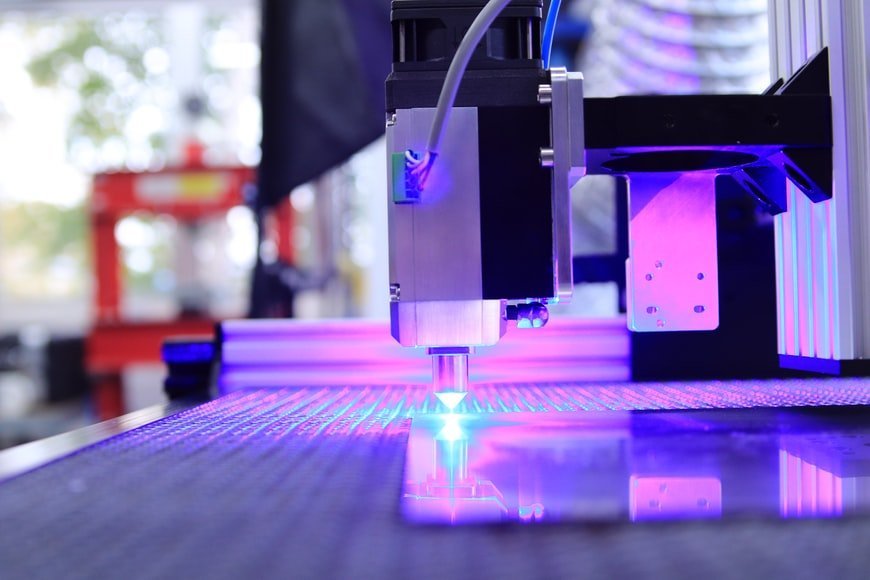

Integrates Contemporary Technology

There is constant evolution and improvement in milling technology and techniques. It ensures the latest advancements make their way through to give manufacturers the best features for their products. Using the latest technology, manufacturers can incorporate complex parts in their products with complete accuracy of production each time.

More Cost-Effective

The CNC milling process can easily be controlled totally by a computer. It does not require manufacturers to bear the cost of laborers working tirelessly to generate products. It also gives manufacturers the capability of changing output based on the market demands.

Read Also: