How To Measure And Cut Acrylic

by Arnab Dey Technology 11 January 2022

Consider the following factors when purchasing polycarbonate sheets of acrylic (perspex) sheets: Both materials are sturdy, transparent, and lightweight. They’re both easy to cut and weld together because they have a high degree of transparency.

Obviously, the more precise your measurements are, the cleaner and more accurate will be your cuts, as well as the connections between panels or plastic sheets and adjacent walls or other components.

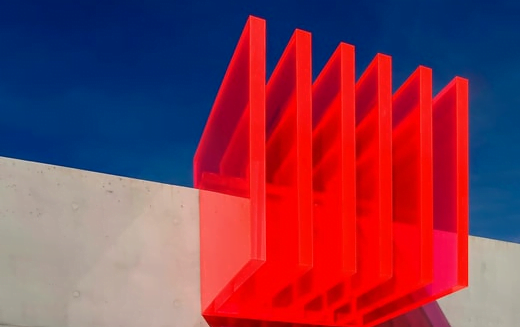

Measuring Plastic For Large Scale Installations

When covering existing walls with plastic sheets for protection, aesthetics, or structural reasons, it is generally best, to begin with, the biggest piece. That describes someone who must fit between two separate walls. When taking this sheet, leave a 2 to 3 mm space on each side for a good yet comfortable fit. When the subsequent sheets are in place, they will effectively fill the gap.

When connecting sheets in a corner, allow for some play so that the following sheet can properly engage. If the location where the sheets will be installed isn’t perfectly square, obtain accurate measurements and then draw them out carefully on the sheet to be cut.

What about measuring tap holes? To calculate the correct diameter in the proper location, measure outward from the center rather than around the hole’s perimeter. The measurement of tapping holes is done to the exact middle of the hole, not its outer edge.

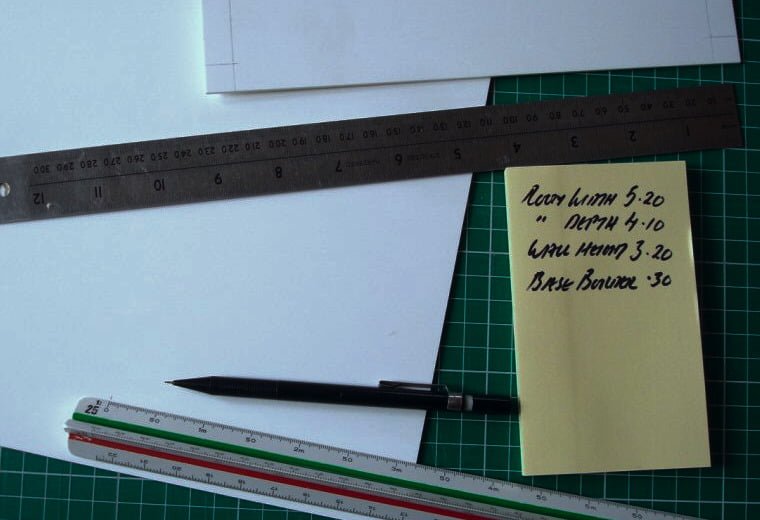

Methods To Mark Measurements

To ensure secure connections, airtight seals, and structural integrity, the cutting or drilling location on the frame must be determined with absolute precision. Perspex sheets may be marked in a variety of ways, some low-tech and others high-tech.

1. Using a magic marker

The most popular and long-standing approach for marking measurements on an acrylic or polycarbonate plastic sheet is to employ a straight edge and magic marker. While this method works well, the marker line width may not be exact enough for some projects. However, owing to its popularity, it has shown to be quite successful in a variety of applications.

2. Using a razor knife

Some users, on the other hand, choose to utilize a razor knife rather than a magic marker in order to achieve high accuracy while also allowing for a line for the cutting tool to follow. In this technique, the cutting line is etched into the paper with remarkable precision. The major advantage is that it can cut anything from tough cardboard to extremely thin materials. The disadvantage is that if you use it to show the cut line while cutting, you’ll scratch it and be unable to repair it. This method necessitates a steady hand, a solid surface, and time.

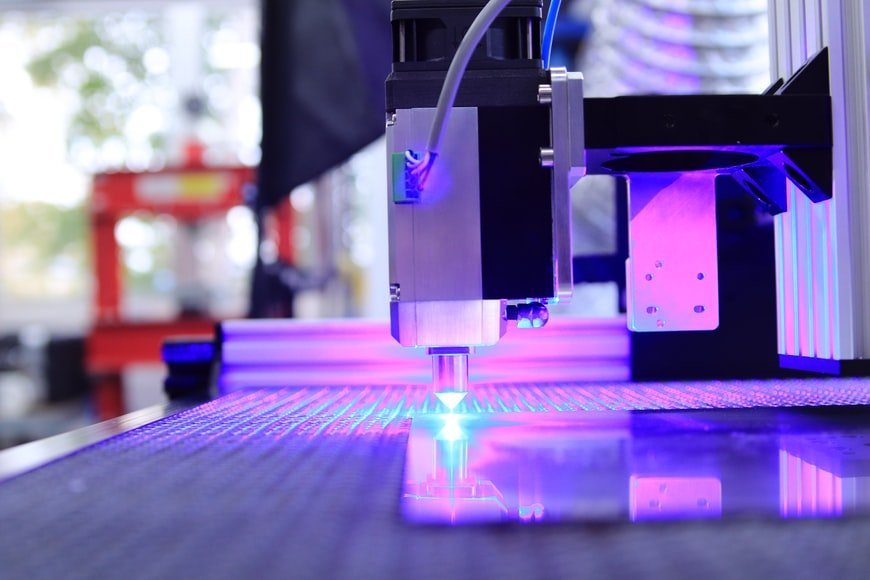

3. Using a laser

Larger, more complex parts are increasingly being produced using laser cutting as a result of their precision and accuracy. Laser cutters have been used more frequently in recent years to assure exactness in measurements and cutting lines. For example, a fiber laser may be used to cut a wide range of commercial polymers including acrylic and polycarbonate sheets.

Additional Reading: