Common Safety Issues & How To Rectify Them

by Sumona Business Security Systems 13 April 2022

Engraving is a design technique that has been used for thousands of years and has evolved and persisted over time, incorporating a wide range of procedures and materials.

Like any other field, Engravers confront a variety of health and safety issues to avoid accidents and other problems on the job.

5 Top Five Fire, Health, And Safety Concerns

Here are the top five health and safety issues that frequently go overlooked in the engraving trade.

1. Fire Outbreaks

According to The Engraving People, small fires are a genuine hazard in the engraving sector, especially when laser engraving at home. When you laser etches your stuff, it’s unusual to see little flames.

Flames that are less than two inches in size generally; extinguish on their own in seconds, but you may need to use a blanket to put out flames that are still burning before they spread.

Flames greater than two inches in diameter should be dealt with using a fire extinguisher.

These fire outbreaks come under patient safety issues in the hospital and healthcare departments. This is the primary safety concern point that every industry and healthcare unit must follow.

As a result, fire extinguishers can be found at the facilities of professional engravers, despite the fact that the chance of fires in such situations is small.

Related Guide: 5 Things Factory Owners Need To Do To Maintain Safety In The Workplace

2. Workspace Cleanliness

Health and safety issues go hand in hand to minimize the risk of harm, so clean workshops are essential for avoiding any hazards. The residue of laser cutting, such as sawdust and other particles in the air, can cause blasts.

Check your workshop frequently to see if anything has caught fire. Any kind of scrap, including wood and metal, can cause a fire hazard since they burn up fast. To decrease any safety concerns, maintain a cluttered and unclean shop on a regular basis.

Of all the food safety issues, workplace cleanliness is the most concerning point. Unless you do not maintain the proper hygiene in the workplace, you can not exactly achieve the maximum customer good feedback.

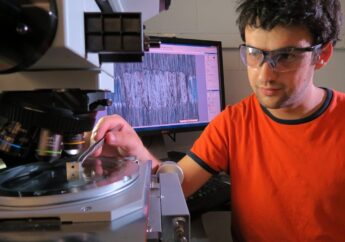

3. Eye Safety

When engraving a variety of materials, safety glasses are required, but many DIY engravers frequently go without this protection. Even a modest laser engraver dissipates light energy that is three times as powerful as the sun’s rays, which means that it may cause eye damage.

Eye safety is the most concerning point in industrial safety issues. This is why most industries do not let their employees pass without wearing safety gear.

The intense light of a laser engraver can harm your cornea, lens, and retina, so it’s always best to wear eye protection before using one.

Related Guide: Health and Safety Training for the Workplace: Resources and information you need to know

4. Materials You Shouldn’t Use

Broad material types of engraving include marble, paper, metal, glass, wood, and fabric. However, it is a big blunder to believe that laser engraving is appropriate for all materials because you may be breathing in harmful fumes.

Even if inhaled in small doses, PVC plastic vapors may be fatal. Therefore you should never work on PVC with lasers.

In addition, fiberglass, polypropylene, ABS, coated carbon fiber, and HDPE are some materials that should not be etched with laser technology.

As a rule of thumb, many professionals are advised for bypassing any of the materials you aren’t sure about, like the flammable things, while laser etching.

Many companies are facing serious charges due to the unhealthy food materials used. Unhealthy material use is the main concerning point for the current food safety issues.

5. Leaving The Lasers Unattended

Despite the fact that multiple laser engravers are pretty quick, certain tasks may need hours to complete. As a result, many engravers frequently turn off their equipment while they work for safety issues.

This, on the other hand, can cause fires and material melting in some cases. Therefore a laser operator must be available at all times while laser engraving is taking place.

If you must take breaks from monitoring, it is usually a good idea to notify a replacement operator before leaving.

Conclusion:

All of these safety issues are pretty concerning for every industry. If you do not take the proper precautions for the safety concerning points, you can not make the right goal or target. Even for some of the industry, the safety concerning points is all. So keep maintaining all these safety concerning issues. And develop the industry.

Read Also: