4 Ways To Step Up Apparel Production With Automation

by Abdul Aziz Mondal Technology 30 May 2023

The apparel industry is constantly expanding, with a projected revenue of almost $2 trillion by 2027 worldwide. One of the main culprits of this growth is none other than automation. Automation refers to the automatic functioning of a machine, process, or system by artificial or electronic innovations that substitute people in terms of observation, effort, and resolution of a problem. With the increased competition in the global market, it became critical for apparel companies to continue to thrive and stay relevant with the use of innovations in technology and manufacturing.

Faced with increased labor costs, innovative fashion manufacturing methods have been used to boost productivity and manufacture high-quality items in large quantities, in short cycles, and at a cheaper cost. Implementing sophisticated technology is one method to enhance such areas while meeting export criteria. The key to developing a successful apparel company is following current trends and implementing them in your everyday activities.

This helps to progress the development of sophisticated items in the global apparel supply and gives a fresh knowledge of how manufacturers may embrace technology while remaining competitive in the global market. Implementing the newest technology is the future of the apparel industry, so read on to find out what type of automation you can implement to continue your business with success.

Implement quality apparel software

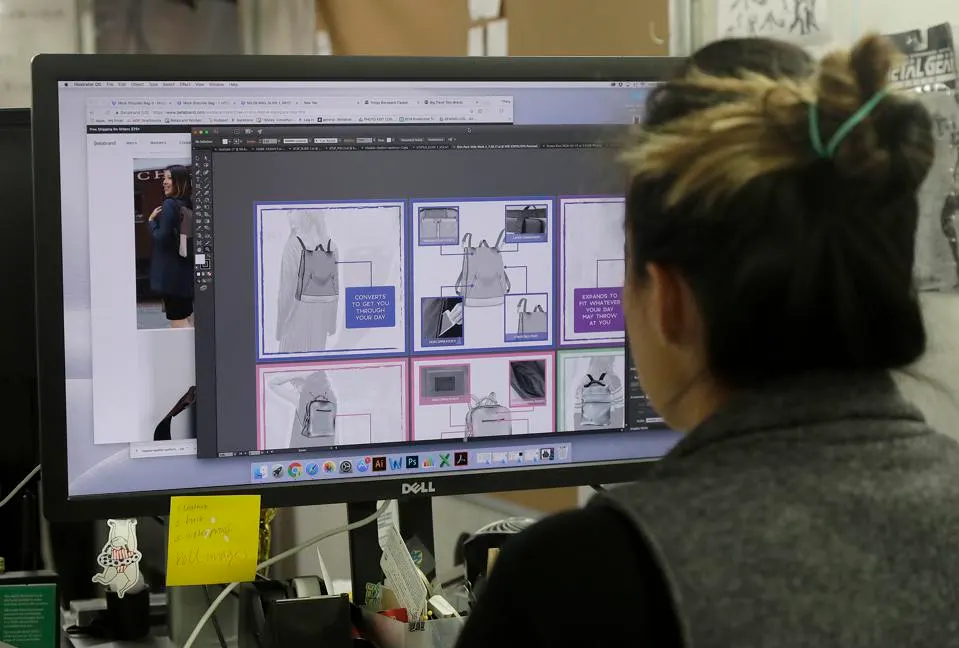

Apparel software consists of automation tools that allow you to connect all departments in your company into one place and manage them simultaneously in order to improve productivity and save time. Additionally, it provides you with real-time data, allowing you to make better decisions and react in a faster way once an issue arises.

Therefore, running a successful fashion business requires investing in the best apparel ERP software to help you streamline your store’s operations and improve company performance. Integrating apparel software into your online fashion store may help you automate a variety of business processes such as inventory management, order taking and fulfillment, return handling, payment processing, and financial record keeping.

Quickly identify and resolve quality issues

With apparel software providing you with real-time data, you will continue to maintain excellent quality services because you will be able to act fast in resolving various issues. This is important because quality issues can lead to wasted resources, decreased operator productivity, and in the worst-case scenario, having plenty of dissatisfied customers.

Implementing a system for comprehensive traceability will help you determine if an end product has a quality issue, so it can be tracked back through the manufacturing process. These automated checks can help you track the problem back to its source, for example, a malfunctioning machine that needs maintenance or an operator who requires further training, and then quickly resolve it.

Implement smart monitors

Automation is also assisting the apparel industry in solving industry-specific difficulties. Textiles, raw materials, and finished clothes, for example, are susceptible to mold growth, particularly when imported in bad conditions or kept in a humid room. Both mold development and product loss can be prevented if the clothes or raw materials used for the creation of the clothes are stored in a proper room with an adjusted temperature.

Employees can follow the changes in the room and detect ideal environmental conditions for mold growth by using smart monitors that automatically measure temperature, humidity, moisture, and other environmental parameters in pre-set intervals. These monitors are internet-connected and operate 24 hours a day, so they can alert management the moment environmental conditions exceed a certain safe limit. This way, employees can take immediate action to protect the clothing from mold damage and transport them to a more suitable storage room once they are informed.

Start using a laser-cutting machine

The laser cutting machine is an equipment commonly used in the leather and apparel industries. The cutting head of the laser is controlled by a computer, so it is very precise and that is why many fashion designers prefer to use this technology. For instance, in synthetic textiles, the laser melts and fuses the synthetic fibers at the edges, resulting in well-finished edges which eliminates the problem of fraying of fibers at the edges of cut sections generated by traditional knife cutters.

Final thoughts

Apparel companies will continue to invest in new tools to keep up with the fashion market. So, try to implement the best apparel software to help you streamline all company processes and help your employees with their everyday obligations.

With the automation processes, you can identify issues quickly and thus resolve them even quicker. Additionally, by implementing smart monitors, you will protect the environment in your company and keep all the clothes in perfect condition. Simply be aware of all the changes happening in the industry and try to find the perfect solutions for your own apparel company.

Additional: