How to Improve the Reliability of Your ICP-OES Analysis

by Arnab Dey Technology Published on: 01 February 2022 Last Updated on: 23 February 2024

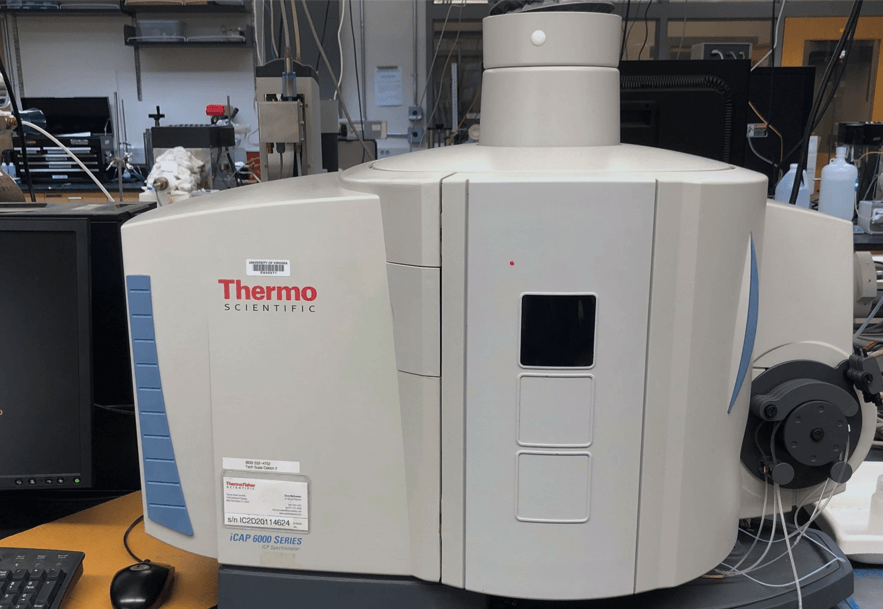

Since the early 1960s, inductively coupled plasma-optical emission spectrometry (ICP-OES) has been used. The technique has been used to analyze everything from normal multi-element analysis of water and soils to wear metals in engine oil samples in the years since its introduction.

ICP OES instruments have a well-deserved reputation for being a quick, accurate, and easy-to-use technology for measuring a wide range of elements down to parts per billion (g/L) concentrations. As a result, it has become a commonplace device in a wide range of laboratories worldwide, with tens of thousands of installations.

What Is The ICP-OES Technology, And How Does It Work?

After aspirating the sample into the plasma via a peristaltic pump, nebulizer, and spray chamber, a high-temperature argon plasma (the ICP) evaporates, desolvates, atomizes (and, in part, ionizes) the chemicals in a (typically) liquid sample.

The plasma’s heat then encourages electrons in the outer shells of the atoms (and ions) to higher energy levels once these processes have transpired. When excited atoms and ions migrate to cooler parts of the plasma, the electrons return to their original shells, producing a spectrum of wavelengths unique to the element to which the atoms and ions correspond.

The light is collected and reflected by a set of mirrors, then passed through a prism and onto a diffraction grating, which resolves the various wavelengths into the picometre range, allowing them to be detected by a photosensitive detector like a charge-coupled device (CCD) or a charge injection device (CID). You need to have qualifications to operate this, just like you will need one for a purge and trap concentrator.

What Types of Samples Can Cause Issues, What Are These Issues, And How Can They Be Resolved?

Saline matrices (e.g., seawater, brine), metal alloy digests, heavy organic compounds (e.g., engine lubrication fluids), and volatile organic solvents are the samples that cause the most issues for ICP-OES.

Coating the radial view window by deposition of the sample matrix can also occur with dual axial/radial view systems, resulting in an increasing reduction in light transmitted through the window as the analysis progresses. Fortunately, there are a variety of options for dealing with these issues.

1. Nebulizers

ICP-OES requires nebulizers to convert liquid samples, which plasmas can’t tolerate in large amounts, into a small aerosol that they can handle. The basic nebulizer with ICP-OES systems is a tiny glass concentric capillary device.

2. Torch Injectors and Spray Chambers

The spray chamber in ICP-OES eliminates larger droplets from the nebulizer’s aerosol while allowing smaller droplets to flow into the plasma. This is required for efficient conversion of the plasma sample into atoms and ions and the maintenance of a stable emission signal.

3. Torch with Plasma

The plasma torch is the part that controls and directs the argon fluxes needed to develop and maintain a stable plasma. Standard torches are made of quartz, which works well for simple applications with low matrix levels and non-corrosive samples.

4. Argon Humidifiers and Sheath Gas Adaptors

A sheath gas adaptor ICP OES instruments fitted between the spray chamber and the torch. This prevents high salt samples from crystallizing in the injector tube by providing a supplemental argon flow that tangentially wraps the sample aerosol preventing it from touching the injector tube.

Read Also: