Vibratory Bowl Feeders: The Key To Successful Material Handling

by Sumona Technology 24 March 2022

Material handling is the process of moving materials from one place to another, be this in a factory, a particular machine in an assembly line, or indeed between one factory and another. Without using the vibratory bowl feeders, the process can be labor-intensive and time-consuming.

Especially when it comes to unloading a truck, where machines like forklift trucks and the use of pallets can help, thankfully, as mentioned above, many different machines have been created to help with this task. However, one machine that is often overlooked is vibratory bowl feeders.

What Are Vibratory Bowl Feeders?

These feeders are designed to provide a continuous material flow during the moving process by using vibration and gravity. Vibratory bowl feeders can be used with a wide variety of products, making them an economical solution for almost any company looking for their next piece of equipment.

Here are some reasons why you should invest in vibratory bowl feeders today!

How Do They Work?

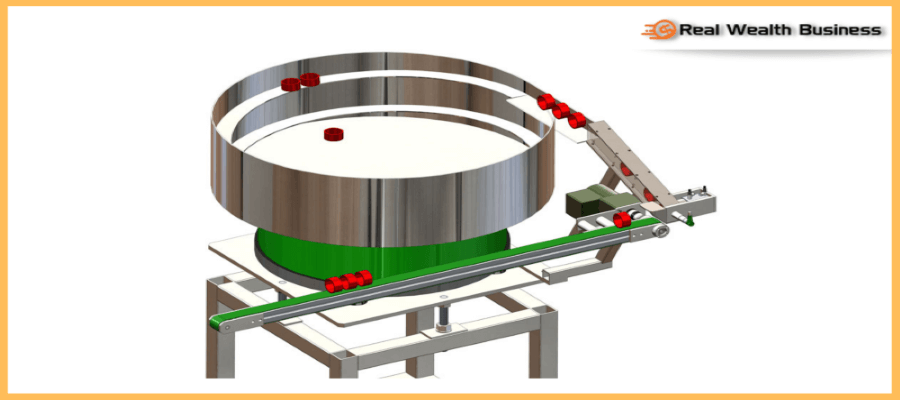

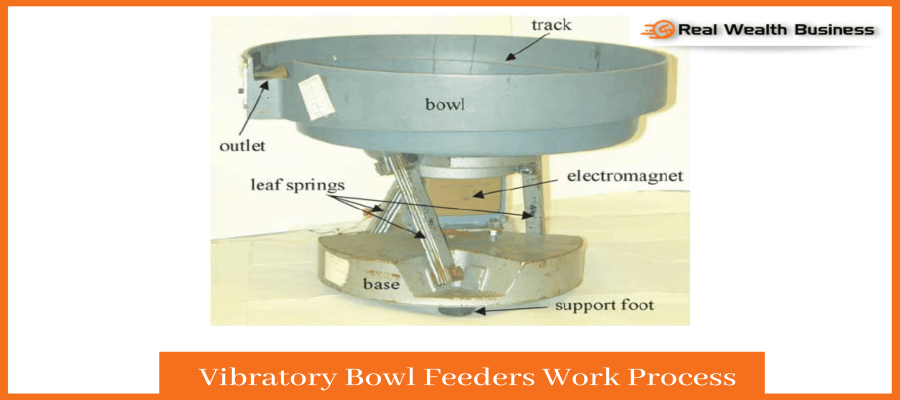

The vibratory bowl feeder uses vibration in order to move an object from one place to another. It usually features a large bowl-shaped container specifically designed to handle the component in question. This is important if the operation of the bowl is to ensure the correct orientation of that component as it is passed to the next machine/stage.

As the name suggests, the parts in the bowl (usually being fed from a hopper) are gently vibrated as they move on a spiral track inside the bowl. The vibrations are induced by a vibratory drive unit, which is itself commanded by a ‘bowl controller’.

One of the key things to note here is the word ‘gently,’ the system being well suited to move delicate objects and things like screws.

The main force used to move the materials is gravity, the vibration allowing them to slide around, be correctly orientated (if required), dropping onto a conveyor belt via what is known as an Escapement.

The vibration also helps keep the materials moving, so they don’t become clumped together, even when there are lengthy pauses between batches of materials.

What Are The Benefits Of Using A Vibratory Bowl Feeder?

There are many benefits to using a vibratory bowl feeder, these becoming an essential part of any modern production line.

1. Economical And Capable To Handle Wide Ranges Of Products

One of the most important is that vibratory bowl feeders are economical. They have the capability to handle a wide range of products, which makes them great for any company.

Their efficiency and reliability are also very high, this being important as any blockages in the production line could result in considerable losses.

2. You Can Use Them In Warehouse

They can be used in warehouses, distribution centers, and even truck and ship loading docks. Utilizing vibratory bowl feeders can help you save time and money because they don’t require an experienced full-time operator to monitor/run them, as they are simple to use and virtually foolproof.

Normally, they can be left to their own devices. All the operator has to do is to keep the feeding hoppers full so that the line is not starved of components.

3. Fewer Possibilities Of Bouncing Damages

Normally bowl feeders are used to moving small components and parts around the line. The hopper provides a steady stream of parts to the vibratory bowl– the drop to the bowl from the hopper being kept to a minimum to minimize bouncing or damage – while the bowl feeder does the same for the production line as a whole.

To ensure that all runs well, a sensor is used to monitor the number of parts in the bowl feeder. When this falls below a predetermined level, the hopper vibrates and shakes components into the bowl, ceasing when the set maximum level is reached. This on / off system means that there are always enough parts in the production line without overloading any stage.

4. Enjoy Large Range Of Applications

Vibratory bowl feeders can be found at all the stages in a production line, from the very start where the components start their journey, right to the end, ‘filling and weighing applications’ being good examples of the latter.

They can also be found in intermediate locations, where for some cases, they and the associated equipment are configured to provide multiple parts, all presented in the correct orientation.

Conclusion

The benefits of using a vibratory bowl feeder are many. They are more cost-effective than other types of material handling equipment, save money through reduced human resources costs, whilst also being more reliable. They also increase the level of safety in any line, humans not being able to ensure that all run as they should. After all, humans are humans and can, and do, all too often make mistakes.

For more advice on how and where to use bowl feeders in your automated production line, please do contact Sandfield Engineering. They have decades of experience and a track record of solving engineering problems.

Read Also: