6 Features Associated With Micro Welding Services

by Barsha Bhattacharya Business Published on: 20 February 2024 Last Updated on: 19 October 2024

Micro-welding services are useful in most industries. They help fix potential issues, thus reducing downtime and delays in most operations. However, you should engage highly experienced micro-welding providers to ensure exceptional services. There are various aspects related to micro welding services, and understanding them helps choose the right service. Check out the key features of micro welding services:

1. Precision & Strength

Micro-welding processes offer precise control of the welds, resulting in consistent and accurate welds. The procedure uses specialized equipment to deliver precise heat control. It involves advanced welding equipment such as laser welders, resistance spot welders, and micro TIG welders.

Strength is also worth mentioning. Although microwelds may be small, they exhibit exceptional strength and are highly durable. However, proper material selection is vital to ensure structural integrity when the welded materials are exposed to different conditions.

2. Fine Welds

Micro-welding services use advanced equipment and processes, thus resulting in fine-resolution welded materials. It involves joining tiny parts with tight tolerances, which is vital in some applications such as medical devices and microelectronics. The microwelding processes involve controlled energy inputs. This ensures precise control of parameters such as temperature and energy distribution, which ensures minimal defects.

3. Low Risk of Damage

Micro welding techniques by Micro Weld emit low heat, thus lowering the risk of damage to surrounding materials. This is vital when joining delicate materials or heat-sensitive substances. This is beneficial since it helps maintain high accuracy levels, mostly in precision components.

Micro-welding also produces quality welds with fewer or no defects like cracks and porosity. The welds meet strict industry standards, ensuring high performance and reliability.

4. Cost-effectiveness

Micro-welding requires special equipment but is cost-effective for applications requiring high-quality levels and precision. Since the welds are done efficiently, this may mean quality and material savings, thus reducing costs.

5. Compatibility With Other Materials

Micro welding techniques can be applied to a wide range of materials, including metals, alloys, and even some non-metallic materials like plastics and ceramics. This versatility makes microwelding suitable for diverse applications across industries.

6. Automation Potential

Micro-welding technology keeps evolving and has experienced tremendous changes over the years. Technology has since enabled automation of the welding processes, thus improving efficiency and reliability. Nowadays, repeatability and efficiency are easily achieved in the manufacturing processes.

Type Of Micro Welding

Like the other welding processes, micro welding can be done in various ways. There are four different types of micro welding that are currently in practice. Those are tig micro-welding, mice-laser welding, micro-resistant welding, and flash micro-welding.

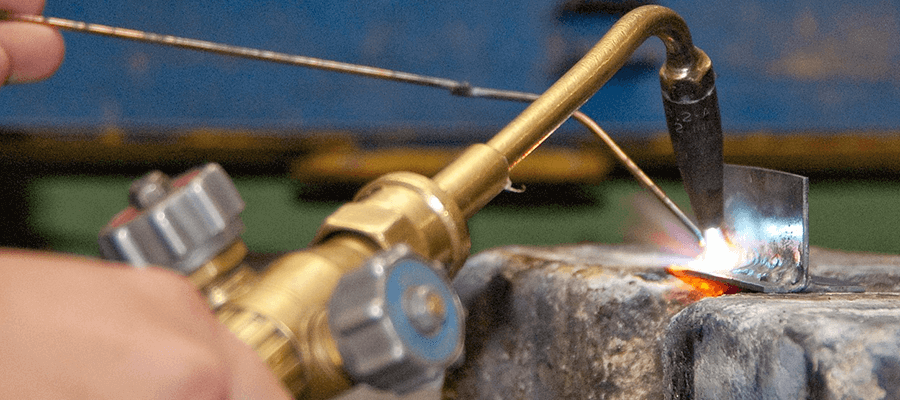

Micro-Laser Welding

The technique of micro-laser welding is laser-driven, and in the process, it does not produce gas. This type of micro-welding uses a laser, which helps create a quality fusion weld with the help of a deep pierce.

Additionally, the fact that it does not produce gas helps avoid contamination from the other surrounding metals. You will also come across micro-laser welding being used for components like automotive, medical, and electronics.

Flash Micro Welding

Flash micro welding is the type that is used to create clean joints with the help of high pressure. This technique uses two metal components that are pressed together and joined together. It is done slowly using a particular temperature, which helps with the process.

This form of micro-welding was developed with production optimization and cost reduction in mind. This type of micro-welding is used for making chains of certain precious metals like silver or gold.

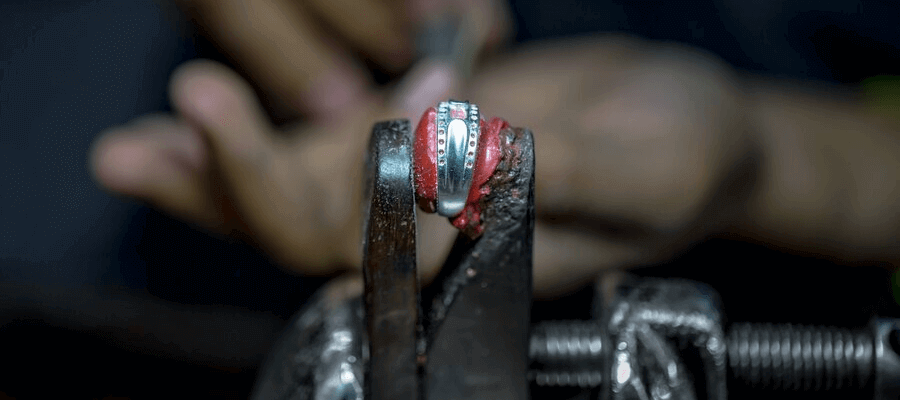

Tig Micro Welding

In tig micro welding, tiny pieces of equipment, which are almost the size of a pen, are used. This small-scale but exact equipment uses the process of gas tungsten to create a weld.

This tig micro-welding allows any welder to apply the placement of any weld and is mostly used in components with a high alloy density. This process produces a lot less residual stress, and it also has more structural integrity.

Micro-Resistant Welding

Micro-resistant welding uses a miniature version of the respective equipment for creating seam welds or minute spots. With the help of this process, two materials are fused, as it lightly clasps the pieces between the electrodes together and applies a specific pressure and electrical flow.

Difference Between Laser Welding And Micro Welding

Micro welding is something that has evolved from traditional TIG welding. This process uses electric current on the workpiece and generates heat at the arc gap point. At this point, they establish a molten tool and introduce the filler rod into this motel pool.

The basic difference between micro welding and traditional TIG welding is that micro welding is generally done at extremely low amperages, combined with some fine control of the range, and used with the help of a high-power microscope.

In the process of micro welding, the technician does the welding repairs in combination with the weld wire section and controls the welding equipment. Laser welding makes use of light energy and heats up the welding zone rapidly.

It melts the filler rod and the adjacent metal joining point. The beam size controls the intensity of the light energy, pulse width, and voltage. It is repeatedly used in different time intervals or singularly used. A high-intensity light source is independently operated, and no current flows through this workpiece.

Where Can I Get Quality Micro Welding Services?

You will get different micro welding companies online. However, not all will meet your needs. Check for various aspects before determining which company can handle your project. Consider attributes like years of experience, cost of services, welding materials used, and project duration. With a professional micro welding company, you can be sure of high-quality products that are highly durable and adhere to the industry standards.

Conclusion

Micro welding ensures high-quality welding with minimal defects. The welds have different features and are compatible with various materials. They are also small, ensuring significant material savings. To get the best quality welds, hire a reputable micro welding company and get the most suitable welds for your needs.

ADDITIONAL READING: