How Much Does Downtime Really Cost In The Manufacturing Industry?

by Mashum Mollah Finance Published on: 21 January 2021 Last Updated on: 22 January 2021

In the last few years, the global manufacturing industry has faced trillions of dollars in losses because of unplanned downtime. If you were to ask manufacturers what is the one thing that they hate and fear the most, 90% of all would state that it is downtime.

When it comes to starting production operations in any facility or factory, the same does not take place at the switch of a button. There are various factors and considerations, which need to be accounted for before actual production starts.

In this article, we speak to leading experts from the world of heavy engineering and manufacturing. We ask them the costs that companies have to incur because of downtime.

Downtime: Meaning and Definition

According to the Oxford English Dictionary, a ‘downtime’ is referred to as the time wherein a machine or a computer is not working, is out of action, or is unavailable.

The term has implications for both the world of computers, networks, software, and servers. It also finds application in the world of heavy engineering and industrial production where machines go broke, require servicing or maintenance.

To break in down, experts have classified downtime under three main heads-

- Mechanical Failure

- Operational Failure

- Electrical Failure

No place of business can afford to have unplanned downtime as it shuts down the entire production line. In the following section, we are going to look at some facts about downtime that are sure to blow your mind away.

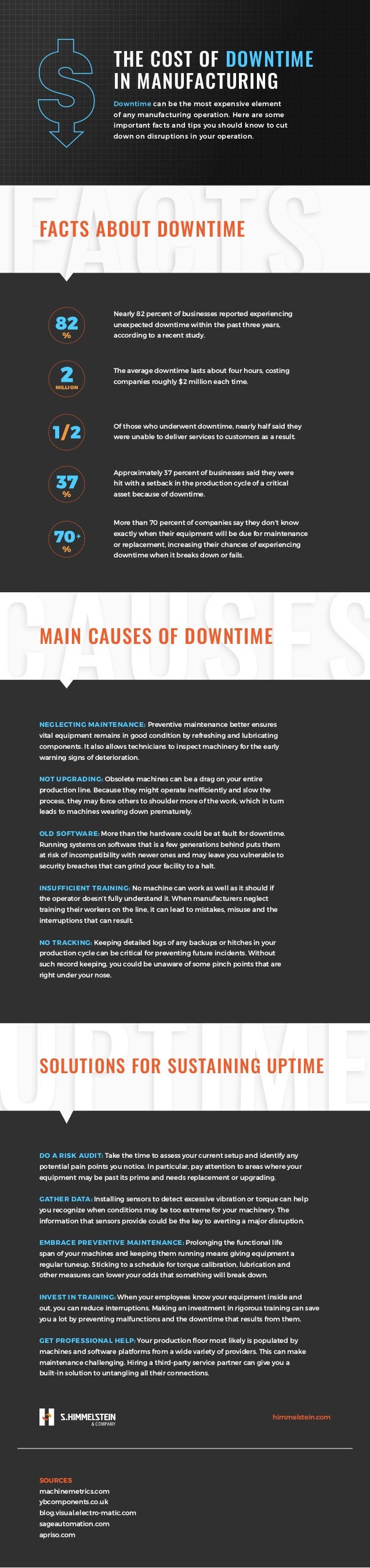

Important Facts about Downtime you need to know about

Let us now try to list down some of the most mind-blowing facts about downtime you need to be aware of-

- According to data, every minute of downtime costs the auto industry roughly $50,000 USD! Just to give it some perspective, one hour of downtime can cost an auto manufacturer $3 Million USD.

- When it comes to human error contributing to downtime, the percentage for the same stands at 23% of all downtime recorded. This is significantly more than human errors in any other business.

- While Faulty Machines and Equipment are another significant cause of downtime, more than 70% of all businesses do not know when their machines and equipment are due for service or maintenance.

- Experts suggest that every manufacturing business suffers from an average of 800 hours of downtime every single year. That is a little more than a month in terms of the number of days lost.

- More than 80% of all industrial units are unable to calculate the real downtime they have faced because of one reason or another. Industrial units lose anywhere between 5 to 20 percent of their productivity because of downtime.

The Final Word

If you are a factory owner, you should be on the lookout for downtime. In fact, holding proper training and orientation programs for employees, checking for machine servicing and maintenance periods, etc. can allow you to counter the evils of downtime considerably.

If you wish to know more about how downtime is detrimental to the interests of manufacturing businesses, refer to the Infographic given below-

A guide created by S. Himmelstein & Company a leading manufacturer of torque tranducers

Read Also: