Improving Productivity With A Pallet Changer Machine

by Ankita Tripathy Business Published on: 07 July 2022 Last Updated on: 03 December 2024

There are many ways to improve productivity in a business, and one of those is by using a pallet changer machine. This type of machine can help to quickly and easily change the pallets that products are stored on, which can save a lot of time and effort in the long run. If you are looking for ways to improve productivity in your business, then investing in a pallet changer could be a great option.

What is a Pallet Changer?

Pallet changers are generally used in CNC machines in order to transport raw or unfinished parts across the production floor. Therefore, it is a very useful and important piece of machinery that has really added accessibility and movability to a business process, making it streamlined and easy to manage.

A pallet changer is a machine that is used to change the pallets that products are stored on. This can be done either manually or automatically, depending on the type of machine that you use.

Pallet changers can be used to change the pallets of products that are stored in a warehouse, or they can also be used to change the pallets of products that are being shipped from one location to another.

Types of Automatic Pallet Changing Systems

Automatic pallet changing systems are great. However, they come in two primary types. Here is a detailed look at the two forms of automatic pallet-changing machines.

However, remember that the technological landscape is changing very fast. Therefore, when you are going through the article, there might be newer models.

Therefore, keep an open mind when approaching this subject. Let’s go!

Shuttle Type Pallet Changer

Shuttle-type pallet changer is one of the oldest forms of pallet changer. This system uses dual methods for pallet changers. This is why it can be a time-consuming process. However, the accuracy rate is higher compared to the other variant.

Nowadays, this form is only found in big CNC machines and is nearly branded as obsolete due to its high tag time. Besides that, this is a significant pallet changer that makes the process easy.

Swing Type Pallet Changer

The swing-type pallet changer is a considerable step up from your run-of-the-mill shuttle pallet changer. This is the only form that has the ability to rotate a complete 180 degrees.

This feature really adds to the overall USP of the machinery. Therefore, making it one of the most prominent pallet changers of today’s world.

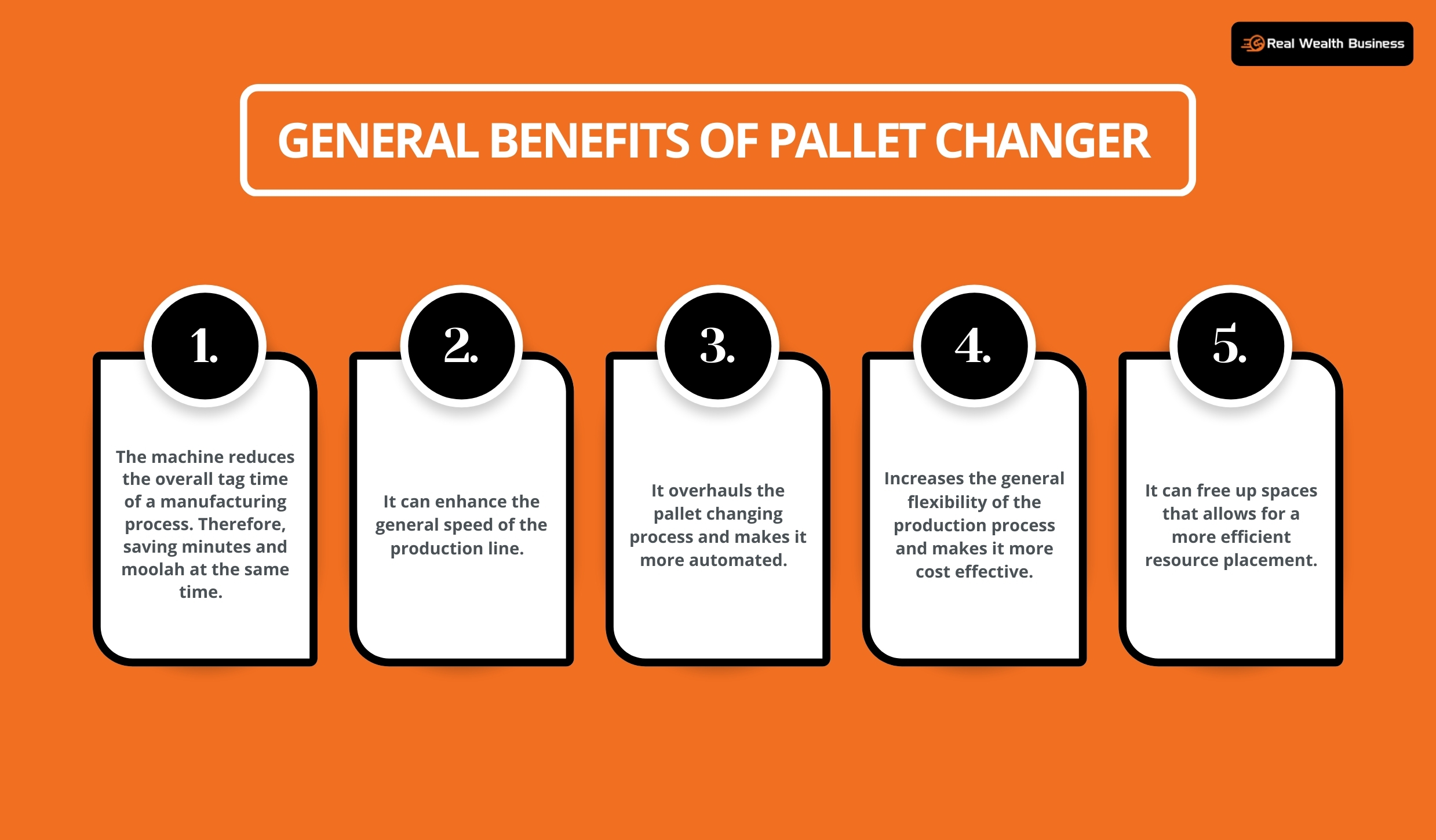

General Benefits of Pallet Changer

Pallet changers are revolutionary. They offer a myriad of benefits to the manufacturing process. Here are some of the most prominent benefits of pallet changers that you need to know:

- The machine reduces the overall tag time of a manufacturing process. Therefore, saving minutes and moolah at the same time.

- It can enhance the general speed of the production line.

- It overhauls the pallet-changing process and makes it more automated.

- Increases the general flexibility of the production process and makes it more cost-effective.

- It can free up spaces that allow for a more efficient resource placement.

Why Use a Pallet Changer?

There are many reasons why you might want to use a pallet changer in your business. One of the most common reasons is to improve productivity. If you have to regularly change the pallets of products that you are storing or shipping, then using a pallet changer can save you a lot of time and effort.

Another reason to use a pallet changer is to improve safety in your workplace. If you are regularly changing the pallets of products, then it is important to make sure that you are doing so safely. A pallet changer can help to ensure that you are changing the pallets correctly and without any accidents.

How do I Choose a Pallet Changer?

There are a few things that you should consider when choosing a pallet changer for your business. First, you need to decide whether you want a manual or automatic machine. Manual machines will require someone to operate them, while automatic machines will be able to change the pallets on their own.

Next, you need to decide what size machine you need. Pallet changers come in a variety of sizes, so you need to make sure that you choose one that is big enough to handle the products that you want to store or ship.

Finally, you need to decide what features you want in your pallet changer. Some machines come with extra features like an attached forklift or a conveyor belt, while others are more basic. Choose the machine that best meets your needs and budget.

How do Pallet Changers Increase Productivity?

Improving productivity with a pallet changer machine can be a great way to save time and improve safety in your workplace. If you regularly change the pallets of products that you are storing or shipping, then using a pallet changer can be a great option for your business.

Choose the right machine for your needs and budget, and you will be able to improve productivity in your workplace. If you want to learn more about how pallet changers can help improve productivity in your workplace, then follow our blog.

We would be happy to discuss the options that are available to you and help you choose the right machine for your needs.

Read Also: