What to Look for in a Quality Wire Form Manufacturer

by Pijus Maity Business Published on: 22 March 2025 Last Updated on: 25 March 2025

If wire forms are part of your product or process, there’s no room for guesswork when it comes to choosing the right manufacturer. A good one can elevate your design, streamline your supply chain, and save you a lot of back-and-forth. The wrong one? That’s a shortcut to quality issues, delays, and costly fixes.

So how do you tell the difference?

More Than Just Bending Metal

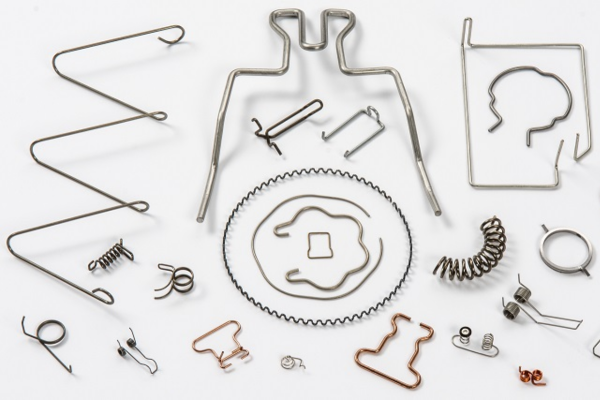

Wire forming might sound straightforward, but it’s rarely as simple as shaping steel into a specific form. The best wire form manufacturer will understand the small design tweaks that can reduce waste, speed up production, or strengthen the final product. They’ll flag potential issues before they become actual problems. And they’ll work with your team—not just for you.

That kind of partnership is hard to measure on a quote sheet, but it shows up where it matters: consistent quality, fewer surprises, and better outcomes.

Essentials: What to Look for

If you want a fast way to size up a wire form manufacturer, here’s a cheat sheet of key things worth checking:

- Prototype to high-volume capability – Can they scale with you as your production needs grow?

- Tooling expertise – Do they design and maintain their own tooling in-house?

- Finishing options – Enamel, chrome, or powder coating—can they handle it or manage it through reliable partners?

- In-house processes – From bending and pressing to welding and coating, how much can they do without outsourcing?

- Supplier network – Do they have access to trusted global sourcing when needed?

- Material knowledge – Can they work with a variety of metals and wire diameters, or are they limited?

- Quality control systems – Do they hold ISO certifications or have structured inspection processes?

- Logistics support – Are they able to help with storage, packaging, or distribution if required?

Think of this as a foundation. The more boxes they tick, the smoother things are likely to go.

Flexibility Is a Superpower

Every business has evolving needs. Today it might be a custom prototype; next quarter, it could be a 10,000-piece run. A wire form manufacturer that only works to a fixed volume or rigid schedule isn’t going to keep up with you long-term.

Look for signs that they’re set up to flex—both in their production and their mindset. Can they tweak production timelines when something shifts on your end? Are they open to non-standard specs or unusual finishes?

The most capable manufacturers aren’t just technically skilled—they’re agile.

Real Operations, Real Capability

If you get the chance to tour a facility or even just see behind the scenes, do it. The condition of the shop floor, the layout of their machinery, and the flow of production tell you a lot.

For example, a setup with twin-head bending machines, press stations, welding, and custom-built tooling areas? That’s a sign of serious capability. If there’s also an on-site coating area or finishing partnerships in place, even better.

These aren’t just technical perks—they translate directly into shorter lead times, tighter quality control, and less logistical juggling.

Communication Isn’t a Bonus—It’s Core

If you’ve ever worked with a supplier who dodges updates, goes quiet after quoting, or leaves you chasing down delivery dates… you’ll know how frustrating it is.

That’s why communication should be part of your decision-making process. Are they clear about timelines? Do they walk you through their process? Are they proactive when something changes?

A good manufacturer doesn’t leave you guessing. They keep you in the loop without making you chase them for answers.

Experience You Can Feel

There’s a difference between a company that’s new to wire forming and one that’s been doing it for decades. Experience shows in the small things—how quickly they understand your brief, how well they manage production flow, and how calmly they handle inevitable hiccups.

And if a manufacturer has been around for a long time and continues to work with a mix of large OEMs and smaller customers? That usually means they know how to adapt and deliver at different scales, without compromising on either end.

It’s Not Just About the Part

When choosing a wire form manufacturer, you’re not just buying a component. You’re plugging into an entire operation: people, processes, supply chains, logistics, and everything in between.

So think beyond just the physical product.

Do they have storage space if you need staged delivery? Can they package and label according to your needs? Are they familiar with international standards if you’re shipping across borders?

The best manufacturers think like partners. They’re already solving problems you haven’t even had to raise yet.

Know What You’re Really Paying For

Yes, pricing matters. But it shouldn’t be the only thing you base your decision on. A cheaper quote that leads to rework, missed deadlines, or inconsistent batches ends up costing more.

So ask yourself:

- What kind of value am I getting?

- Is this a supplier I can grow with?

- Are they solving problems or just filling orders?

When you’re working with someone who’s invested in the long-term outcome—not just the transaction—it’s a different experience altogether.

Go for the Ones Who Make It Easy

A quality wire form manufacturer should make your life easier, not harder. They should get your design, meet your specs, hit your deadlines, and help you avoid headaches along the way.

Whether you’re sourcing shelf guides, oven sliders, mesh inserts, or something more niche, the real difference is in how they deliver.

You’ll know when you’ve found the right one. Things click. Communication flows. And the parts? They just fit—every time.