How Can a Driver Servo Motor Help In Improving Productivity For Your Factory

by Mashum Mollah Business Development 15 July 2019

A Driver Servo Motor is a servomechanism that is essentially automated control structures. These automated control structures are used in a wide variety of industries and manufacturing units.

With increasing automation and robotic use in factories, a driver servo motor has become an absolute necessity. If you are looking to optimize your production capabilities, you will need this device.

A servo driver is highly advantageous as it helps in improving productivity, enhances efficiency and fastens the processes. In recent times, increasing automation especially in industries like automobile manufacturing has necessitated the use of robotics.

Three Main Parameters and Figures to look for in a Driver Servo Motor:

As I have already mentioned above, a driver servo motor is a critical component when it comes to precision control. As such, there are three main components of a driver servo motor that you need to pay attention to.

If you are looking to purchase one, you should definitely ask the company manufacturing them about the following points-

1. Torque Density of the device:

The best motors do not have to be huge and cumbersome to exhibit high torque figures. The best devices in the market are small but powerful. You should be looking to get a high torque figure of around 300-330 NM from your device.

The best driver servo motor manufacturers promise these high torque figures from relatively small devices.

2. High Power of the Device:

In addition to the high torque figures, you would also expect the device to be powerful. Again, small devices made by good manufacturers are powerful. All this power is going to drive the motor and accelerate the process, as well as the precision.

Ideally, you should be looking to extract power figures in the range of 400-450 W. Only such high power figures will be able to make a difference in the production process.

3. High Precision Levels of the Device:

This is probably the most important component of the driver servo motor. We are talking about huge robotic arms and processes assembling cars. Imagine the precision that is required to be successful at the task.

Your device should be able to afford precisions of figures like 0.01 m. I know that this might be an unrealistic level of precision to guarantee. However, the best devices reach these levels effortlessly.

What are some of the Parts of a Servo System?

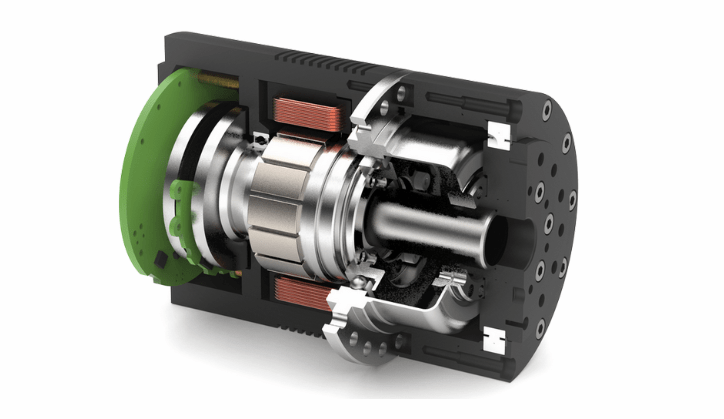

All Servo systems are made up of four main components-

- Controller of the Device-

- Servo Drive

- The motor of the Device

- Feedback Mechanism

The feedback mechanism is a typical encoder in most cases. The controller and the driver work in sync to understand and judge the next course of action of the motor. In other words, they tell the motor as to what its next function is going to be.

The controller is chiefly responsible for sending low voltage electrical energy into the drive. The drive then calculates the requirement of the motor and understands how much electrical energy the motor will need. If the electrical energy is low, the drives create or amplifies the low voltage energy into a high voltage one.

By controlling the torque figures and the velocity of the current, the driver can make the necessary changes for the current. In many ways, a servo driver functions as an intermediate amplifier between the controller and the motor.

The Best Driver Servo Motor in the Industry:

Around 80% of the manufacturers of servo drivers in the industry manufacture them as a standalone component. This means that you just get the driver, and have to figure out where to get the controller and the motor.

This is not the end of all the troubles. You would then need to assess whether the various components (all from different manufacturers) are working harmoniously or not. This leads to many problems, complications, and issues.

The best driver servo motor integrates all four components into one seamlessly efficient device. This means that your controller, driver, motor, and feedback mechanisms are all integrated into one device.

This helps in enhancing efficiency, promotes productivity and stretches the longevity of the device. You would not have to keep purchasing such high-performance components regularly. This is known in the industry as an all-in-one driver servo solution.

When you are purchasing one from a manufacturer, ensure that it comes with a warranty and support.

Read Also: