What Makes Tungsten Better Than Other Metals

by Abdul Aziz Mondal Technology Published on: 09 November 2022 Last Updated on: 15 March 2025

Tungsten is second only to industrial diamond in hardness and has been shown to outlast most metals. So, it is no surprise that it is currently the preferred method for increasing the longevity and performance of numerous industrial parts.

As one of the most robust metals available, tungsten is resistant to scratches and tarnishing. Furthermore, this uncommon and unusual metal has a permanent polish that never dulls.

About Tungsten

Tungsten is one of the most extraordinary metals. It possesses the greatest melting point of any element yet found, as well as a high density and resilience to corrosion and thermal deformations.

It also combines well with other metals to generate alloys and carbides. Tungsten carbide, abbreviated WC, is a compound composed of carbon and tungsten. Tungsten has the highest melting point at 3422 °C and the highest strength at temperatures above 1650° C.

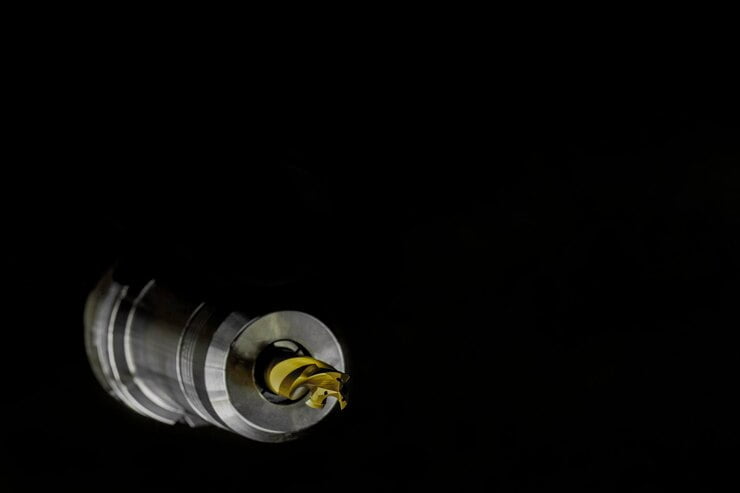

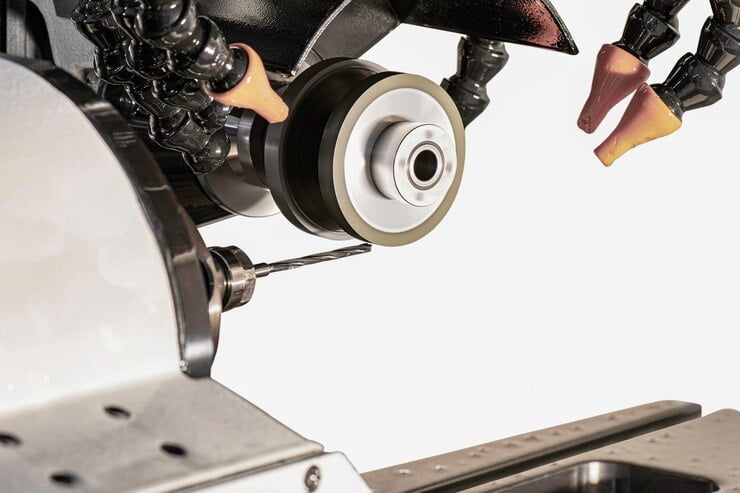

Tungsten, which means “heavy stone” in Swedish, is mostly used in compound or alloy forms, such as tungsten carbide brazing rod, and its main application is in the mechanical engineering industry. Extremely hard, tungsten carbide components must be machined using ceramic or diamond tools to resist the numerous demands of intense manufacturing settings.

These WC components can sustain high compression stresses while maintaining superior wear and oxidation resistance at high temperatures.

Benefits of Using Tungsten

There are many different brands of tungsten carbide pellets, Tungsten carbide grit, and Tungsten Composite Rods to pick from in today’s ever-changing fishing tackle industry. They are extremely popular due to the widespread use of Tungsten in manufacturing. A key component in this is the carbide rod, which typically serves as the foundation for many tungsten-based products.

China Carbide manufacturers often play a crucial role in supplying high-quality carbide rods that enhance strength, precision, and longevity. These rods are widely used in cutting tools and industrial wear parts, ensuring consistent performance across various applications.

1. It’s High-Density

Tungsten has extremely high density. In fact, at 19.3 g/cm3, tungsten has one of the greatest densities of any metal, measuring nearly 19.3 times that of water and 1.7 times that of lead. Because of this feature, tungsten can retain substantially more weight in smaller packaging – it is widely employed for applications requiring mass in small proportions.

It’s an excellent material for ballasts and kinetic weapons that must be tiny and streamlined while conveying a lot of energy. It is also utilized as a good alternative metal for jewelry creation. Tungsten can be said to have the same density as gold but is significantly cheaper to purchase.

As a result, it has often been utilized to produce counterfeit gold bars since the 1980s, either by coating a tungsten bar with gold or punching holes in a genuine gold bar and inserting tungsten rods.

Tungsten is frequently used to make heavy metal alloys. High-speed steel, which may contain up to 18% tungsten, is an excellent example. However, the density of tungsten can be advantageous when mixed with nickel, copper, iron, and other elements.

2. Economic Advantage

Tungsten Carbide enhances the life of worn components. Studies suggest that it may boost life by 4 to 10 times over heat-treated steel, minimizing downtime and increasing time spent in the field.

However, the surface hardness of the Tungsten Carbide does not only increase wear life. A correctly designed component that uses the metal in the correct places will be much more efficient at getting through the soil, with minimal smear.

3. Fabrication Sturdiness

Tungsten is the most durable metal, with the highest tensile strength of any pure metal. While this can render it brittle in some situations, tungsten’s stiffness means that it can be formed into very thin wires without shattering during the metal manufacturing process.

The usage of tungsten in light bulb filaments is perhaps the most visible example of this. In this application, you must heat extremely thin wires to extremely high temperatures to generate light, and tungsten’s high melting point is critical in allowing this to happen.

4. Corrosion-Resistance

Tungsten is extremely corrosion-resistant and may be used in harsh settings and outdoor applications. It is especially beneficial when extended contact with corrosive chemicals, such as water, acid, or solvents, is expected.

A maritime environment is a common corrosive environment that many metals cannot handle. Many metals are particularly corrosive to salt water in particular.

However, when alloyed with other metals, tungsten’s resilience makes it particularly suitable for such a severe environment, allowing it to be utilized in shipbuilding, fishing lures, and jewelry.

5. Agronomic Advantages

Tungsten Carbide used in critical regions maintains the shape and design of the item, guaranteeing maximum performance throughout its life.

Without Tungsten Carbide, the edges deteriorate and become rounded, making it more prone to smear and compress the soil while going over it. A worn part’s compressive, smearing action works on the earth at deep. This is frequently necessary for early crop emergence and vital root development when cultivating.

Smearing at this level, in any case, produces a barrier for root development, water, and airflow. These smearing obstacles are exacerbated when the soil is humid. Adequate water and air circulation are critical for crop establishment and development.

6. High-Temperature Resistance

Tungsten can be useful in some situations because of its heat resistance, especially when contrasted with other, more common metals.

Tungsten carbide pellets, for example, are a superb material for high-temperature conditions, which is why it is so commonly used in the aircraft, automatic, and construction sectors.

Tungsten metal is also often employed in the production of alloys and superalloys. Its exceptionally high melting point and resistance to thermal creep contribute to the alloy’s strength, allowing it to be used in more thermally intense applications where other metals would fail.

7. Electronic Structure

Wrought iron is commonly utilized in the electronics sector and situations with high radiation levels due to its conductive characteristics and relative inertness.

Because of this, tungsten is a popular metal for X-ray targets and another high-energy radiation shielding, as the relatively inert, extremely high-density substance is difficult for x-rays to penetrate.

Tungsten metal is also often used as electrodes, conductors, and metallic films.

Conclusion

Tungsten carbide powder for sale is widely available at neighborhood retailers, sporting goods stores, and online.

This is because tungsten metal has found applications in practically every sector, from jewelry and sports to medical instruments, aerospace engineering, high-speed equipment, nuclear shielding, alloys and compounds, chemical applications, and electronics, thanks to its outstanding qualities.

Tungsten is also being studied for nanowires, making it attractive for future material, science, and technology development.

Additional: