Tips For Servicing Your Woodworking Machinery

by Abdul Aziz Mondal How to Guides Published on: 10 August 2023 Last Updated on: 11 March 2025

Following a good maintenance and servicing routine for your woodworking machinery will ensure the longevity of the tools and your safety while working.

Regularly servicing your woodworking machinery will keep it clean and free from dust and oil. Further, servicing includes greasing the machinery when necessary.

However, servicing your woodworking machinery for long life will present many challenges to you.

So, you may contact a reliable company like Calderbrook Woodworking Machinery, which offers a rebuilding service that can help you with those issues you cannot deal with yourself.

However, do you know the perils of not servicing your woodworking tools? What kind of servicing do your woodworking needs, and what are the quick servicing tips for the tools?

We will cover all the aspects in the Real Wealth Business guide.

Why Is It Important To Service Your Woodworking Tools?

Depending on the amount of usage your woodworking machinery gets, cleaning, maintenance, and even servicing may only take a few minutes each day with the right schedule in place.

It may also be necessary to spend a couple of extra minutes on this task every week or month to ensure that your machinery is performing at its optimum.

However, we often neglect regular servicing of the woodworking tools, inviting operational and financial repercussions.

If the equipment is not maintained properly, it will be subject to early wear and tear, which will lead to costly repairs or replacements.

Furthermore, your tool will start malfunctioning without proper servicing. This will cause downtime and impact workflow, causing the project cost to shoot up.

In addition, with regular servicing of your tool, you will create a safer work environment and will not face compliance or regulations-related issues.

Overall, professional servicing of your woodworking machinery will result in long-term savings by eliminitating the expenses of regular repair, create a safe working place and keep the workflow intact.

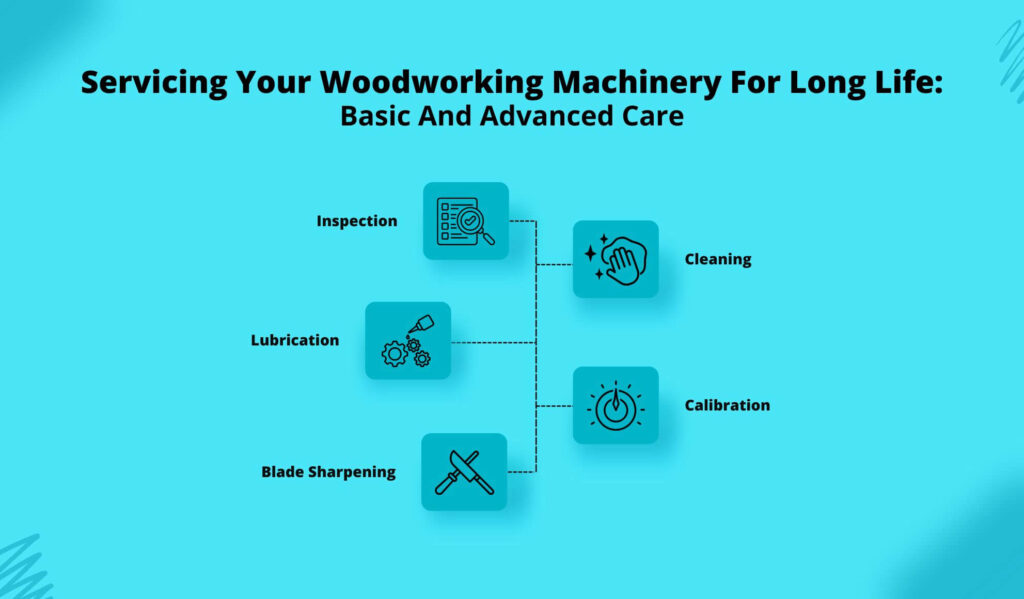

Servicing Your Woodworking Machinery For Long Life: Basic And Advanced Care

Servicing your woodworking machinery for a long life includes basic care and advanced maintenance.

Let’s have a brief idea about them.

- Inspection

Regular inspections help to identify the areas of malfunctioning in your tools. So, with proper inspection and diagnosis, you will easily identify problems and visual issues like loose screws, frayed cords, and worn-out blades.

- Cleaning

Your woodworking machinery may have stubborn grime, and you will need compressed air or detergent solution to clean it.

- Lubrication

Regular lubrication reduces the risks of wear and tear in gears, joints, bearings, and other moving parts of your woodworking machinery.

However, the lubrication of your woodworking tools must be done according to the guidelines of the manufacturers. Further, wiping off the extra lubricant is essential to avoid the accumulation of grease, dirt, and oil.

- Calibration

Calibration is essential, and advanced care for tools like torque wrenches, levels, and laser measures. It is important to calibrate on time to ensure the readings are correct and the tools are working reliably.

So, you must seek professional assistance for calibration.

- Blade Sharpening

Blade sharpening is an advanced care regime for saws, chisels, and all types of cutting tools to maintain operational efficiency.

Depending on the tool you use, you will need to sharpen it manually using files or stones, or you may even need to use an electronic sharpening tool.

Quick Tips For Servicing Your Woodworking Machinery For Long Life

These are some professional and quick tips for servicing your woodworking machinery for a long life.

1. Employing the right tools for each task

You might be wrong if you think you can get away by working with the same tool for every activity. In order to optimize their potential, ensure to use the of suitable equipment for suitable jobs. For example, when it comes to small operations like slippage, use screwdrivers without bothering big equipment.

2. Prevent the formation of rust

The next step is to prevent your woodworking equipment from getting rusted. To serve this purpose, it is critical to keep them dry as well as clean. If they are in the habit of getting wet while working, make sure to disinfect them and pat dry before storing them.

3. Sharpen them every other day

Often, we hear that the sharper your tools are, the longer they are going to last. Maintaining sharp equipment not only helps in doing the precise job but also keeps you safe. Dull blades are most likely to slip and cause injuries to the concerned person. On the other hand, it is easy to hold and control sharper tools.

4. Oil them on a monthly basis

Woodworking is all about using the equipment until it gets tarnished. But do they always have to be like that? Regular oiling actually smoothens the different parts of your equipment. Some experts suggest applying turpentine or tar on the tool handles for extra moisture as well as bacteria protection.

5. Follow safety protocols

Safety must be the first priority when it comes to using hand tools. Nobody is really immune to accidents, not even professional craftsmen. Small considerations like wearing gloves and taking safety precautions can actually keep you safe from accidents.

6. Cleaning Your Machinery

It is important to ensure that before you begin any form of maintenance or cleaning on any of your woodworking machines, you make sure they are unplugged. You should be careful not to touch those areas of the machine that are marked as “not for user servicing.”

You also need to make sure that the products you use on your machines are suitable for the job at hand – it may be necessary to refer to the handbook to make sure that you are using the right products. If the products you use are not designed for your machine, they have the potential to make the machine unsafe to use.

7. Use Dust Extractors

In a woodworking environment, dust is an unavoidable issue. Ensure that you have fully working dust extractors in place and that these are regularly cleaned and emptied for maximum efficiency.

You should also ensure that any loose dust and wood shavings are swept up on a regular basis. Caught underfoot, they may cause someone to lose their footing, and they also represent a fire hazard. This is a much quicker job when it is done at regular intervals.

8. Greasing And Lubricating Tips

Ensure that you have the right grease and lubricant for each machine.

This may vary from one machine to another based on the type of work the machine does.

Greasing and lubricating your woodworking machinery will help ensure it works as efficiently as possible.

A sluggish machine may well be in need of some attention in this area.

The Bottom Line

Follow the aforementioned tips for servicing your woodworking machinery for a longer shelf life and operational efficiency.

Furthermore, keep your tools dry, clean, and rust-free to avoid regular wear and tear.

Moreover, be particular about the storage of these tools and keep them only in pegboards, shelves, or toolboxes.

Also, maintain a checklist of the servicing requirements and schedules for the tools you use.

Additional: