How to Choose Your Plastic Manufacturing Process?

by Ankita Tripathy Technology Published on: 19 March 2022 Last Updated on: 06 December 2024

Production and cost efficiency are the top two factors manufacturers are pursuing except for good quality. Manufacturers these days use technological combinations to achieve their needs. Here, we will talk about Injection molding Vs 3D printing and how you can use both techniques at once.

Manufacturers are now using both techniques to their benefit. Here, you can understand how they’re working.

Injection Molding

Injection molding is a process suitable for more significant production with excellent finishing. First, they use tools to create mold. Then, they pour melted plastic into the mold and, in the end, get the finished product as per the design.

This is a more efficient and cost-effective method of manufacturing plastic parts or components. However, since the bloom of the customization market, low-volume custom injection molding has come out to meet people’s needs.

Figure 1 – Injection Molding

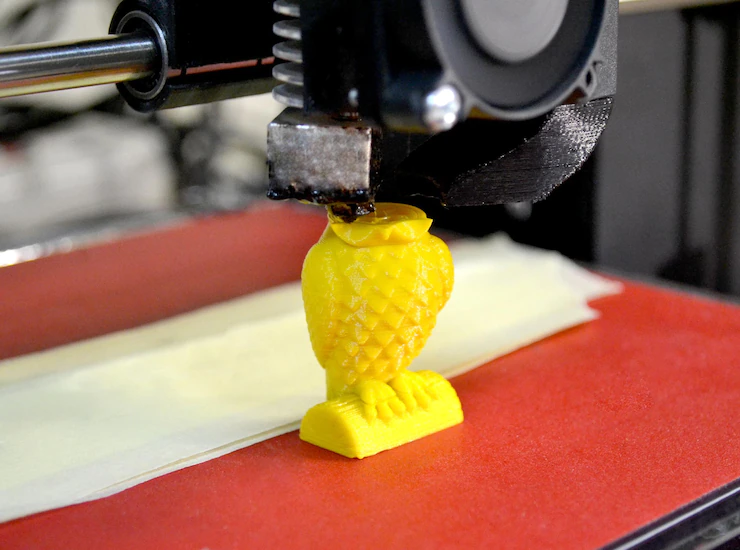

3D Printing

Making every piece is relatively slower than molding but a good choice for small parts or prototypes. Special printing devices are used in this method to print plastic layers. The production time of each component or part takes the same time, which makes it a good choice for short-scale production.

Figure 2 – 3D Printing

Types of Equipment

While using 3D printing, you will need the filament (raw material) and a 3D printer. You can use any desktop or laptop to operate the printer, making it a cost-effective printing method for fewer parts.

On the other hand, in the injection molding process, you will need a molding machine that melts and injects the plastic. The mold then shapes the plastic into the desired design. But before that, you have to create the mold using metal such as aluminum, stainless steel, etc. Developing the mold is a time-consuming and costly process. However, the production speed is higher after making the mold than in 3D printing.

When to Use 3D Printing?

- 3D printing is the best solution when producing a manageable number of parts. Here you don’t have to spend money on tooling. So, if you need small batches, you should use 3D printing.

- If you need prototypes for R&D purposes, you should use 3D printing. It takes less time, costs less, and you don’t need an aesthetic and exemplary finished product for R&D.

- If you need any immediate change, you can use 3D printing. You can even pause the printing and resume by immediately changing your design. You can’t do that in injection molding as you must undergo the entire retooling process.

- If you need quick production in 1 or 2 weeks, you should use 3D printing.

- 3D printing is excellent for relatively small plastic components and parts.

- Though Injection molding can produce any intricate shape or design, sometimes ejection from a mold can create complications.

When Should You Use Injection Molding?

- Though the turnaround time for injection molding is slightly high (4-7 weeks), the production speed is much higher than 3D printing once the tooling is done.

- Injection molding is a very cost-effective method for more significant volume production. The cost dramatically reduces when you increase the volume (More than 100 pieces) of production parts.

- There are no or few separations or breaks in the molding process, which occurs in 3D printing frequently.

- There are no limitations for product or size in the injection molding. You can produce any size product at any scale using injection molding.

- The finishing of injection molded products can have a wide variety and be smooth. On the other hand, 3D printing always shows a printing layer and needs additional finishing most of the time.

- If you are preparing prototypes for pitching purposes, you should use molding to provide prototypes with better finishing.

Using Both Techniques for the Best Outcome

Using both techniques simultaneously and for the same projects can save time and provide excellent results sooner.

Combining both techniques in the same project can enhance the testing time, and in the end, manufacturers can go for large production sooner than expected.

3D printing can provide prototypes exactly enough close to the design. But sometimes, it becomes hard to implement mechanical testing in many prototypes. However, modern 3D printing and injection molding have resolved this issue.

Though most 3D printers are polymer-based, metal printing technology has evolved over the last few years. Using this process, manufacturers can improve the tooling which was challenging with conventional machining.

In robotics and many other technologies, the combination of these two methods has made some significant improvements.

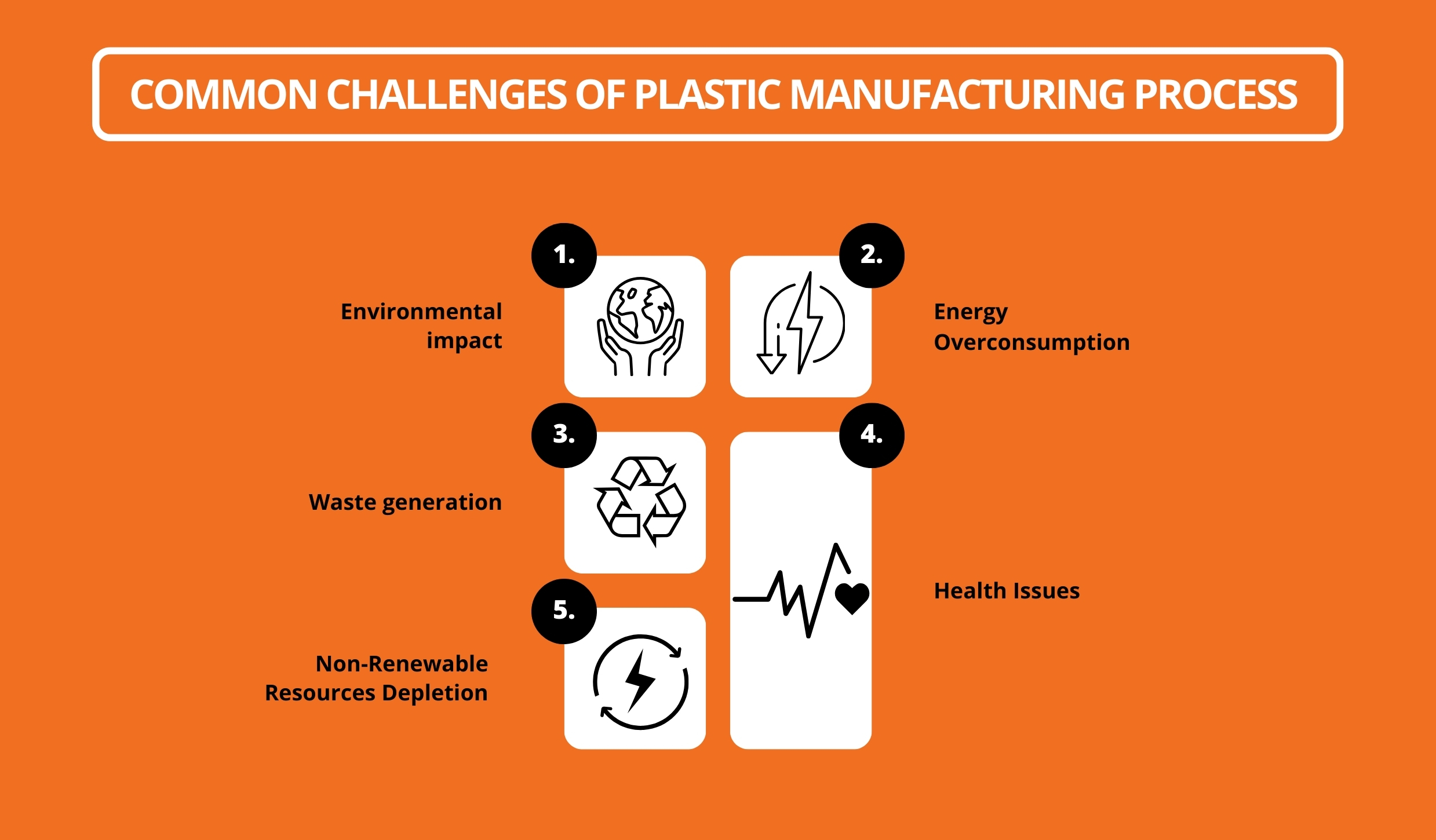

Common Challenges of the Plastic Manufacturing Process

Plastic is one of the most used components in today’s business world. Everywhere you look, there is plastic usage. Business is booming.

However, that does not mean that everything is hunky and dory. Here are common challenges that you might face during the plastic manufacturing process:

- Environmental impact: The plastic manufacturing process has a wide-scale ecological effect. This includes many different results like water pollution, land pollution, etc.

- Energy Overconsumption: producing plastic is not easy at all. It is a highly energy-intensive process.

- Waste generation: Plastic manufacturing can emit vast amounts of waste. Waste can affect the average ecological balance of the world.

- Health Issues: Microplastics are microscopic plastics that contaminate our water system and soil. They have far-reaching consequences on our health and mental faculties.

- Non-Renewable Resources Depletion: Plastic is primarily made using petroleum. Petroleum is a non-renewable resource that is rapidly depleting. This is a significant cause of concern for many.

Conclusion

Injection molding and 3D printing are both convenient manufacturing processes. And there is no competition between these two techniques. Manufacturers can use any of these two methods for their benefit.

Besides, combining injection molding and 3D printing can help manufacturers get better results sooner than the conventional method.

Read Also: