Improve Processes and Production With SCADA

by Mashum Mollah Technology Published on: 27 December 2018 Last Updated on: 11 November 2024

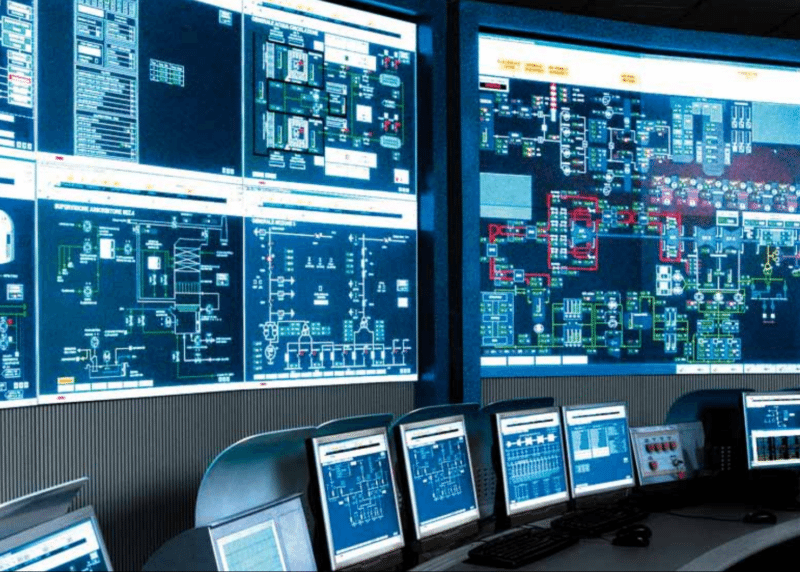

SCADA, supervisory control and data acquisition, is used in a variety of industries, including energy and power, food and beverage, oil and gas, and many, many more. SCADA systems are used to control processes by directly interacting with devices for more efficiency. The SCADA system includes hardware and software that is used to gather and process data in real time. It also monitors processes and record events. The data is displayed on a human-machine interface (HMI), a computer screen, which allows any problems to be identified and resolved as quickly as possible and results in savings of time and money. Processes that are malfunctioning can be reprogrammed by the operator without using a programming language.

Processes and Production With SCADA:

SCADA has been around since the ’50s and has evolved along with the more sophisticated technologies. Using current IT (information technology) and web-based applications, SCADA improves efficiency, productivity, and reliability in many industries. SCADA and Automation services are designed by highly-skilled experts who also provide on-site training and offer options to fit your budget. Whether you are starting your own production line or want to scale up, adding SCADA or using automation to update and increase your current production can provide more efficient processes and greater control over every part.

A small town in Illinois, La Salle, was forced to upgrade the SCADA system it installed in 1992 to control the water system. It no longer functioned properly. It was used to control the city’s water towers, pumping stations, and eight wells. It communicated information, such as water levels in the water towers with a computer at the main plant, turned on and off pumps, and maintained proper water pressure in pipes. When the SCADA system failed, a water tower overflowed and operators clocked many more hours of overtime, checking the water levels and turning on and off pumps manually.

By hooking new computers to the existing fiber optics at the water towers, booster pump stations, and using wireless signals for the wells, the new SCADA system increased reliability and security while lowering overtime pay. SCADA monitors water usage and adjusts pumps and water tower levels, saving energy. Adjustments and changes are made from the data collected. The 19-inch touchscreen allows operators to monitor the system. A remote Internet server stores and accesses data and computing services in the cloud. SCADA systems help things function smoother when used to control traffic lights, utilities, and processes in manufacturing plants.

Since every business is different, having an automation engineering company that understands and designs specifically for your operations is important to reaping the benefits of SCADA and achieving optimal efficiency. The control systems engineer knows the right combination of hardware and software to meet your needs and fit your purpose. PLCs (programmable logic controllers) and RTUs (remote terminal units) are microcomputers that communicate with other machines, devices, and sensors to route information through SCADA software. The SCADA software processes distributes and displays this information for operators to analyze and make decisions in real time.

SCADA system’s data also allows products to be traceable, which is a great advantage in the food and beverage industry. When there is a recall of a product, the data is easily retrievable to identify ingredients or products throughout its processing. The origin, packaging, and distribution of the product allows it to be identified, traced or removed before it leaves. SCADA system also helps manufacturers meet the standards of food quality and safety. It prevents errors, provides data in one centralized location, puts many processes on automatic, including temperature control. It makes processes easier for operators to control and monitor, revealing potential problems so that corrections can be made before defective products are distributed.

Using SCADA and automation services to optimize your manufacturing and production can improve your processes and increase production and profits. Take a closer look at how SCADA and automation services can be added to or improved upon in your processes and consult with an automation engineering company. You can realize better processes, increased production, and greater profits for your business or company. SCADA is for small and large business and especially for a business that intends to grow and increase its production. No matter the industry, SCADA and automation services give you greater control and efficiency.

Read Also: