Facts About Productivity In The Factory

by Abdul Aziz Mondal Business Development Published on: 26 February 2018 Last Updated on: 21 May 2025

The Value Of Optimization :

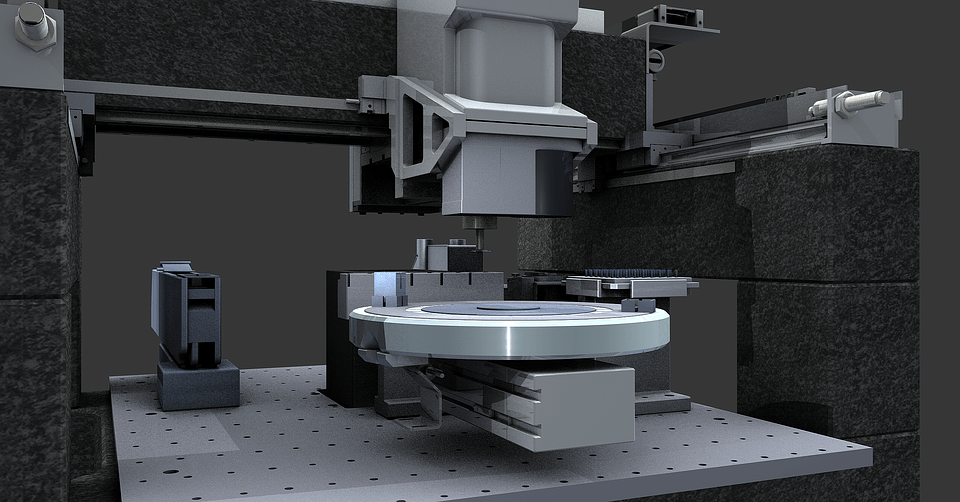

Smart Manufacturing is a means of optimizing production using technology like IoT, or the Internet of Things. Basically, modern resources are brought to bear on the manufacturing floor. This allows trends to be identified which would be invisible otherwise. Whether trends are good or bad, if they are visible, they can be dealt with.

The truth is, with any sort of factory production, there are going to be many little details which seem inconsequential, but over time can end up costing tens of thousands of dollars. For example, consider the cost-savings from outsourced stampings as opposed to in-house stamping.

Say you’ve got a precisely stamped instrument which is required for the assembly-line construction of some machine component your factory makes. What if that precisely stamped instrument were only for one thing your organization produces? And is precise stamping something done cheaply? You’d have to run your own stamping company to get it right with the precision an outsourced solution could.

One way many manufacturing organizations are optimizing their production is through Weiss-Aug.com; according to the site, this organization started out 45 years ago: “…as a precision metal stamping company focusing on supplying miniature high-speed stampings with extremely tight tolerances to meet our customers’ intricate and complex stamping needs.” The site goes on to note that it provides services that are cutting edge by utilizing: “…numerous new industry leading capabilities and technologies to meet the needs of [a] modern client base.”

Some Hypothetical Numbers :

If you’ve got your stamped instruments for the machine you produce in advance, they can simply be applied—rather than designed and made—during manufacture. This will likely save you time. If you save thirty seconds per machine and produce 200 in a 12 hour a day, that’s one hour and forty minutes which can be devoted to additional production. If you were able to produce just 2 extra machines per day in a 24/7/365 factory, that’s 730 machines. If each was sold for $100, that’s $73k.

Little changes can make a big difference. If you’re able to source machine-printed parts more cost-effectively than designing and building them in-house, this could help you produce more merchandise, thus increasing your profit. Smart Manufacturing helps identify pressure points such as these that can be augmented for greatest profitability.

Another area of infrastructural operations that’s worth optimizing involves digital organization. You’re going to need time management solutions. Being able to clock in or out through a cloud option that automatically categorizes everything can save time and effort, reducing personnel infrastructure needs. Additionally, some organizations provide previously-designed management solutions worth considering.

Take Microsoft Excel spreadsheets, for instance. Getting options that are better than typical Excel timesheets may be easier than you think; Clockspot.com has created solutions for your convenience—according to their way of thinking: “Excel might not be a perfect solution, but, if you’re going to use it, why not make sure you have the best templates at your disposal?”

Information Technology And Streamlined Operations :

Additionally, look at the technology which keeps your factory afloat. Is it contemporary, or is it behind the times? How about your IT? Do you have to hire a full-time IT staff for management? That’s costing you hundreds of thousands a year, in all likelihood. But for much less, you can outsource to a Managed Service Provider and get the same service.

When it comes to factory production, today’s technology options make things more streamlined and optimized than they’ve been in modern history. If you haven’t already, it makes sense for you to take close stock of your factory’s needs, and see where you can upgrade. This can be done gradually or all at once, but neglecting such a solution might be compared to leaving money on the table. That’s intolerable given the costs of business! Accordingly, you need to find the right solutions.

Read More :

1. 5 Ways To Use Technology In Your Business

2. 5 Different Ways to Raise Capital for Your Business Without a Loan