What Does a Float Switch Do?

by Arnab Dey Technology Published on: 13 January 2022 Last Updated on: 27 May 2025

Float switches are often used to automate control operations in applications where the liquid level must be monitored, especially in large containers, tanks, or reservoirs. These switches are often connected to a valve, a pump, or an alarm. Before we look at the different types of float switches and their applications, let’s first understand the basic working principle.

What is a Float Switch and How Does It Work?

A float switch is a device used to monitor the liquid level in a tank, reservoir, or sump pit. When the fluid level is low or high, the float switch moves with the water, and based on its orientation it will either connect or disconnect an electrical circuit. This electrical circuit can then activate a pump, a valve, or an alarm, depending on how it is wired.

In water tanks, for example, a float switch will actuate a water pump if the water level falls below a given threshold, allowing more water to flow into the tank. Once the water level rises above the maximum allowable limit, the float switch will once again switch off the water pump, stopping the flow of water into the tank.

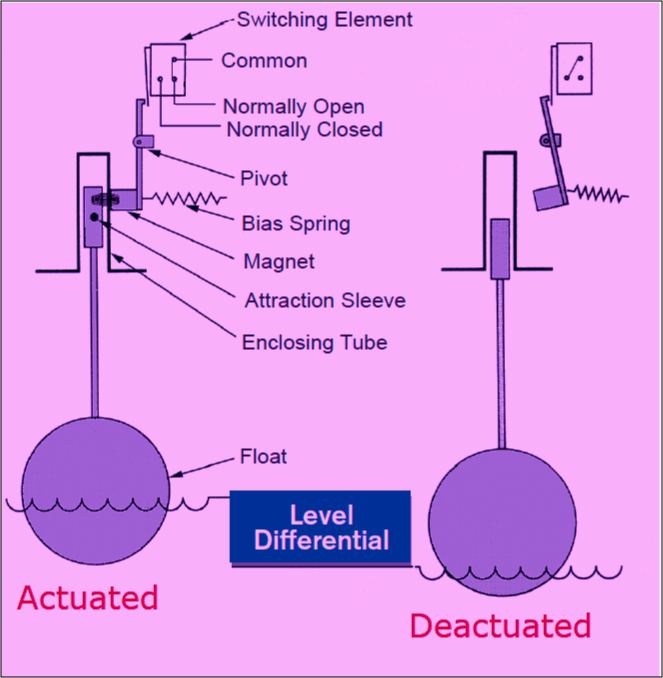

The float switch rises with the liquid level and consists of two main components, an internal switch/sensor, and a hollow floating body. It’s also worth noting that a float switch is mechanical, so it opens and closes due to gravity, i.e., as the water level moves vertically up and down.

Switching Method and Wiring

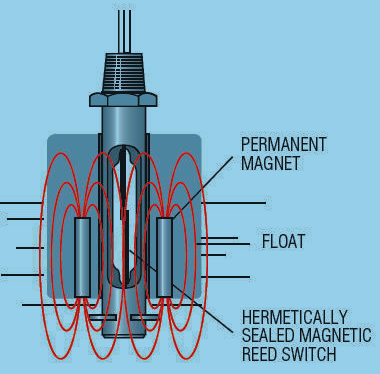

Most float switches in the market use the reed switch technology with a magnet that controls the closing and opening of the switch. Ideally, a reed switch has two ferromagnetic leads positioned close to but not touching in a hermetically-sealed glass cylinder. When the magnet is between the two leads, it is a closed circuit. When the magnet is moved away from the leads, it is an open circuit.

The rising/falling liquid level controls the float switch angle, which then controls the position of the magnet. Therefore, based on if the circuit is open or closed based on the magnet position, it can control other components. For example, if it is wired so that a closed circuit turns a pump on to pump water out of a reservoir.

Then, as the water rises and gets to a set threshold, the float switch rises and due to gravity, the magnet comes into contact with the leads closing the circuit. This circuit is connected to a pump that pumps water out of the reservoir. When the water drops (due to water being pumped out), the float switch will fall and the magnet will fall away from the leads creating an open circuit and turning off the pump.

When installing a float switch, you should check if it has a fixed point or an external counterweight. Switches with a counterweight have pre-determined angles at which they operate. They also have a maximum/minimum cable length for optimal operation.

Another classification to make is the NO and NC float switches. A normally closed float switch is one in which the circuit is closed when the floating body is going down. So once the liquid level rises to the highest allowable level, the circuit opens. With a normally open switch, the vice versa is true.

Types of Float Switches

There are three main types of fixed point float switches. These are:

1. The KPM Series

This is a highly reliable float switch ideal for monitoring clean water and other types of liquid media. The KPM float is quite common in the market, and it opens/closes the circuit at a negative/positive 45-degree angle. So basically, the liquid level at which this switch will operate depends on the length of the cable from the counterweight to the switch.

2. The MPM Series

The MPM switch is commonly used in sewage water applications due to its design, shape, and large size. The MPM switches have a double liquid-proof design, which helps protect the inside of the switch. It opens or closes the circuit at a negative/positive 45-degree angle. This switch also requires a counterweight, and the fluid level at which it operates depends on the length of the cable from the counterweight.

3. The JPM Series

The JPM series switches are tilt-level switches consisting of a heavy body free of irregularity. This float switch does not require an external counterweight, making it ideal for use in turbulent water and other industrial wastewater applications. The JPM series switches are often used in pairs to enable two operations, filling and emptying.

Float Switch Applications

Some of the common float switch applications include:

- Sump and sewage pits – used to monitor and activate a sewage pump that controls the rising sewer levels.

- Water tanks and reservoirs – float switches are used in water tanks and water reservoirs to control the water levels. This helps prevent water overflow or the tank/reservoirs from running dry. These switches are often connected to a water pump.

- Refrigerant and AC systems – float switches used in such applications often help monitor the water levels for optimal system operation.

- Beverage industry – float switches are used to fill and empty beverage tanks.

- Industrial washers – float switches help control the washer’s water levels.

Closing Comments

Float switches are mechanical devices that use gravity due to the dropping/rising liquid levels to control on and off circuit operations. When choosing a float switch in the market, you should pay attention to the switch’s design, voltage & current rating, possible wiring circuits, and their typical use cases. That said, you can always seek professional help during the selection process to avoid buying the wrong product.

Read Also: