7 Advantages of CNC Machining for Mass Production

by Abdul Aziz Mondal Technology Published on: 02 October 2021 Last Updated on: 30 January 2025

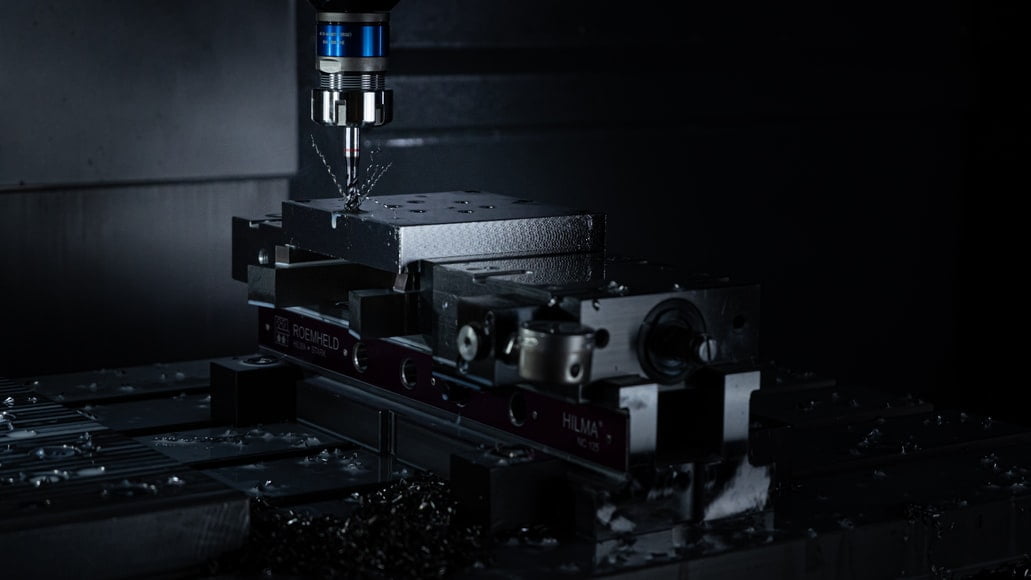

Technological advancements have greatly influenced the mass production of goods. CNC machining is one of the most important machine processes that are commonly used in large-scale manufacturing firms to produce products with high levels of accuracy and speed.

Since creating an identical product for every customer has become crucial, CNC machining has emerged as a highly beneficial process for businesses. The benefits of CNC machining are quite significant, which is why it has become a preferred method for producing goods at a fast rate and with high accuracy levels. Here are some of the major benefits that CNC machining offers.

Increased Design Flexibility

A significant benefit you can enjoy by using CNC machines is their ability to provide design flexibility. They can produce parts with varying designs and sizes, which means businesses do not have to worry about the availability of part replacements.

Prototyping companies can also use CNC technology to create prototypes and quickly make changes as per their demands. This saves time and money since you don’t need to go through the entire process to make changes.

Since most components used in manual machining are manufactured only once, there is a high chance that you may have to scrap or store these parts when replacements are required. This is not the case in CNC machining, as it uses components that can be easily replaced when damaged.

Consider Reading: IoT functionalities for smart manufacturing.

Higher Precision

CNC machines possess higher levels of accuracy than manual machining. They can manufacture parts with such precision that it sometimes becomes difficult to differentiate them from ones created manually.

One of the key elements contributing to this precision is the use of bonded abrasives in the finishing stages. Wondering what makes up a bonded abrasive?

A bonded abrasive is composed of two main components, including combining abrasive grains and a bonding material to form a solid, rigid structure.

By utilizing these tools in conjunction with CNC technology, manufacturers can achieve a level of smoothness and refinement that is crucial for many industries, from aerospace to medical device production.This is why businesses choose CNC machining over other manufacturing techniques, as it results in products that are more accurate and reliable. It reduces the chance of defects and increases the efficiency of production.

Minimal Maintenance

Another benefit that makes CNC machining more beneficial than manual machining is its ability to produce parts with minimal maintenance. Manual machining requires high levels of supervision and maintenance, which is not compatible with mass production.

While CNC machines require some level of attention during the process, they are highly efficient when it comes to reducing labor costs. They also speed up the entire manufacturing process, making it more reliable and cost-effective.

Consider Reading: 3 Technologies That Have Changed Manufacturing.

Cutting Down Costs

While CNC machining can significantly reduce labor costs, it also requires fewer raw materials. The components used in manual machining are discarded after the process is completed, which makes them more expensive than parts created through CNC machines.

Less waste after CNC processes also makes this technology environmentally friendlier than other technologies. It’s a step towards sustainability which is critical for the long run.

Part replacement is another considerable factor that adds to the overall cost of manual machining, while the need for replacement is non-existent in CNC machines. This is another reason why companies prefer CNC machining over manual machining.

Increased Production Capacity

The higher productivity that CNC machines offer makes them more beneficial than conventional methods of manufacturing. It enables businesses to produce high numbers of goods in very little time, which in turn reduces the lead time required for production.

This also further reduces labor costs because companies do not have to spend more on labor. CNC machines require less supervision, making the process far more beneficial for businesses.

Increased Reliability

One of the major benefits that you will enjoy by using CNC machines is increased reliability. CNC technologies are known to produce high-quality components that can last for a long period of time without requiring maintenance.

This enables businesses to create products that will deliver high levels of performance and efficiency for years together. Using CNC machining also helps companies avoid the need for part replacements, which would have been a costly affair if done using manual machining.

Increased Productivity

One of the major benefits that businesses can enjoy by using CNC machining is its ability to increase productivity. This is due to the number of components that can be produced in a single day.

CNC machines are capable of producing a greater number of parts per hour compared to manual machining. This makes it easier for businesses to handle large production orders without compromising on quality, reducing lead times and increasing efficiency.

Final Thoughts

The high degree of accuracy and precision offered by CNC machines ensures that defects are almost nonexistent. With growing business competition in today’s market, every firm needs the best manufacturing techniques in order to deliver products on time.

CNC machines help businesses not only produce high numbers of goods in short periods of time but also offer increased flexibility when it comes to designing parts. This ensures that companies can create products with varying designs and sizes without compromising on quality or performance.

Read Also: