Why Scraped Surface Heat Exchangers Are Essential In Viscous Product Processing

by Barsha Bhattacharya Business 07 May 2025

The efficient processing of highly viscous products has unique thermal challenges that conventional heat exchange equipment cannot adequately address.

Scraped surface heat exchangers are the definitive solution for manufacturers handling products with complex rheological properties, from chocolate and caramel to pharmaceutical compounds and specialized polymers.

Below, we’ll examine how these specialized heat transfer systems overcome the limitations of traditional equipment while delivering superior processing results for challenging high-viscosity applications.

| The Viscous Fluid Production And The Current Business LandscapeViscous fluid production and business comprises a better understanding and management of fluids with high internal friction or good resistance to flow. It applies to various industrial applications. The current market for viscous fluids has become broad. It encompasses several types, such as silicone fluids and fluid viscous dampers. The projection says that growth will surge in the upcoming years. For example, the silicone fluids had a growth of 6.71 billion USD in 2024, and will rise upto 10.03 billion USD by 2032. Industries such as personal care, automotive, food, and other industrial sectors will drive this growth to a massive percentage. |

The Engineering Principles Behind Scraped Surface Technology

Understanding the fundamental mechanics of scraped surface heat exchangers reveals why they excel in applications where other heat transfer equipment falls short.

Their design addresses specific challenges inherent to the processing of viscous materials.

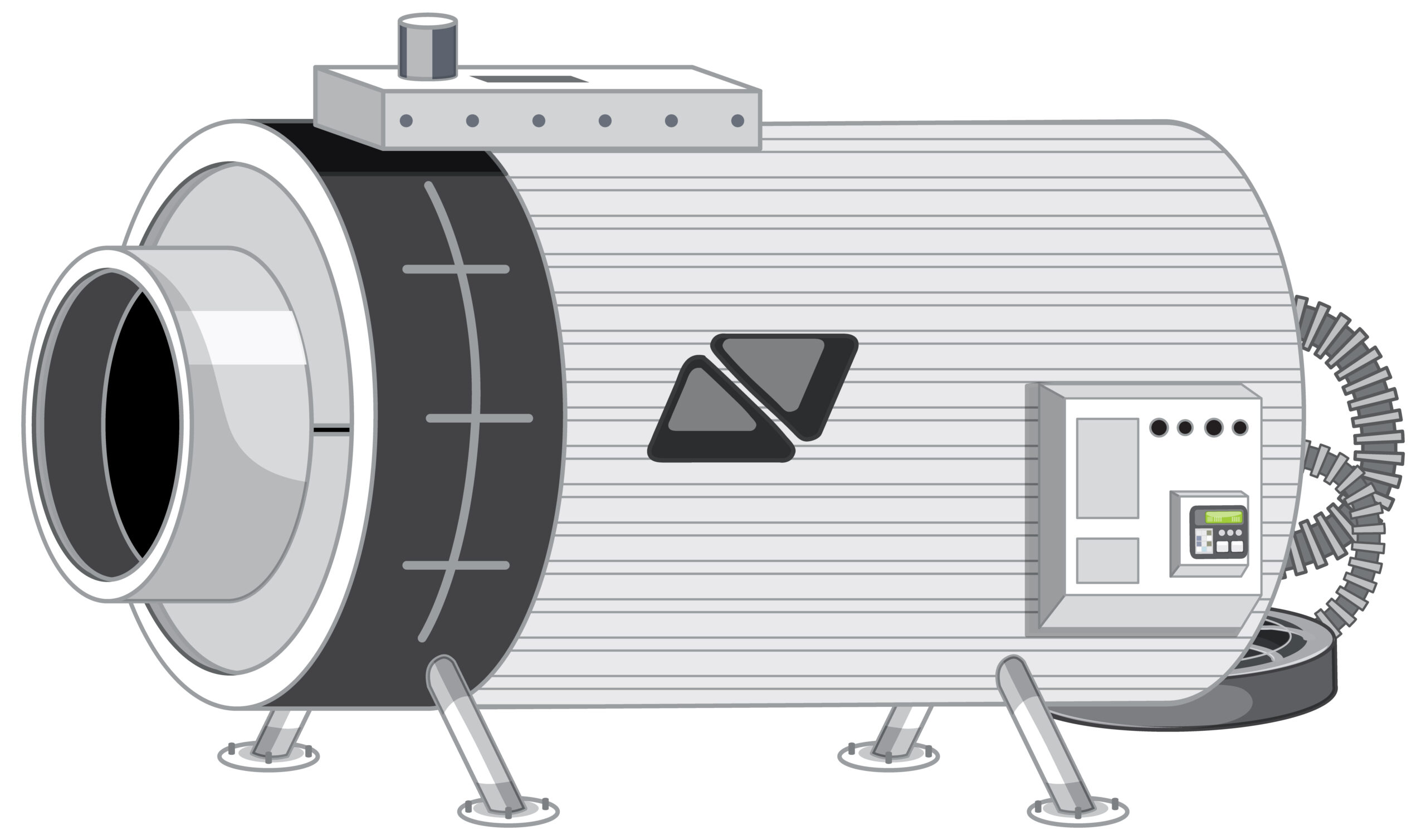

At their core, these systems employ a stationary cylindrical heat transfer surface surrounding a rotating shaft fitted with scraper blades.

As the shaft rotates, these blades continuously remove product from the heat transfer surfaces. This can help in preventing the formation of an insulating boundary layer that would otherwise impede efficient heat transfer.

The continuous scraping action yields thermal efficiency rates up to five times higher than conventional shell-and-tube exchangers when processing high-viscosity materials.

The critical design elements include precise blade-to-wall clearance (typically maintained at 0.3-0.5 mm), specialized blade materials selected for specific product characteristics, and variable rotational speeds that can be optimized based on product viscosity profiles.

Modern systems incorporate independent drive mechanisms that allow rotational speed adjustments without affecting flow rate, providing unparalleled processing flexibility.

Applications Across Industries

Scraped surface heat exchangers are highly versatile, making them essential across various industries. Their specialized design allows them to tackle specific processing challenges unique to each sector.

- Food Production– These systems excel in crystallization processes for margarine, shortening, and confectionery, where precise temperature control ensures the right texture and mouthfeel.

In dairy applications, such as ice cream production, they support controlled nucleation and crystal growth during freezing, improving product consistency.

- Chemical Processing – These heat exchangers facilitate reactions that require stable temperature regulation.

This particularly occurs when handling substances that undergo significant changes in viscosity during processing. Their efficiency ensures smooth and controlled thermal management.

- Pharmaceutical Manufacturing – Scraped surface technology enables gentle yet thorough crystallization and polymerization, protecting product integrity while ensuring precise control over formulation.

- Personal Care Products – Temperature-sensitive formulations with complex rheological properties benefit from the consistent thermal treatment these systems provide.

This preserves product stability and sensory characteristics, ensuring a reliable consumer experience.

Operational Advantages In Manufacturing Environments

Besides efficient processing, scraped surface heat exchangers provide key operational benefits that enhance manufacturing productivity and product consistency.

One major advantage is product changeover efficiency. The continuous scraping action leaves minimal product residue, reducing cleaning time between production runs and lowering the risk of cross-contamination.

This is especially beneficial for facilities handling multiple formulations. Implementing well-designed Clean-in-Place (CIP) systems further streamlines changeovers, optimizing overall workflow.

Energy efficiency is another significant improvement over conventional systems. Their enhanced heat transfer coefficients allow lower temperature differentials to achieve the same processing results, reducing overall utility consumption.

This can result in 15–30% energy savings in refrigerated applications, depending on the specific operating conditions.

Additionally, correctly specified scraped surface systems reduce maintenance demands. Continuous product removal prevents fouling, eliminating the need for frequent cleaning cycles and reducing production interruptions.

Advanced seal technologies in modern designs further extend equipment lifespan while minimizing contamination risks.

Efficiency As A Competitive Advantage For Scraped Surface Heat Exchangers

Imagine this: You are running a business that focuses on producing very thick and sticky products, let’s say, like some sauce or gel sort!

This is exactly the kind of production where the Scraped Surface Heat Exchanger shines bright! These machines are specifically designed to handle any viscous material without clogging the outlets or slowing down the process.

The Scraped Surface Heat Exchangers always ensure the production runs smoothly and efficiently. This results in less waste and more products in the batch, along with fewer stoppages in the production.

If you are running a business, you would already know how crucial it is to achieve faster inputs and reliable schedules.

You would spend less time fixing equipment and more time producing the desired products. Greater efficiency would also improve the bottom line.

All these small cost savings, efficiency, and productivity can be a great boost against the competitors, even when the industry margins are tight!

How To Reduce Energy Costs For Long-Term Profitability Through Scraped Surface Heat Exchangers?

Energy bills are always counted as a major expense in the processing facilities, and the good news? Scraped surface heat exchangers play a huge role in reducing the overall cost.

All thanks to the smart design, the exchangers transfer less heat, which leads to the overall reduction of the cost, even with the thick, viscous products.

On top of that, if you can conduct a continuous scraping, it can help in reducing the overall product buildup on the heating surface! This means the system does not have to work hard to maintain efficiency and temperature.

As a result, you can achieve lower energy usage along with the bills. Now, what will happen if your energy usage goes down? Well, it can help you increase your overall profit.

So, yes! For the long run, the SSHEs can make a significant impact on cutting the operating costs.

This can be considered an amazing, smart move to achieve sustainable wealth while staying competitive in the marketplace.

Wrapping It Up!

Scraped surface heat exchangers are essential for processors handling viscous materials with challenging thermal properties.

Their unique mechanical action creates processing possibilities that would be unattainable with conventional heat transfer equipment.

For manufacturers seeking to optimize the production of high-viscosity products, these specialized systems deliver the ideal combination of thermal efficiency, product quality preservation, and operational flexibility.

Investing in properly specified scraped surface technology yields returns through improved product consistency, reduced energy consumption, and enhanced production efficiency.

Read Also: