Follow These Steps to Improve Your Warehouse Operations

by Ankita Tripathy Business Development Published on: 12 July 2022 Last Updated on: 03 December 2024

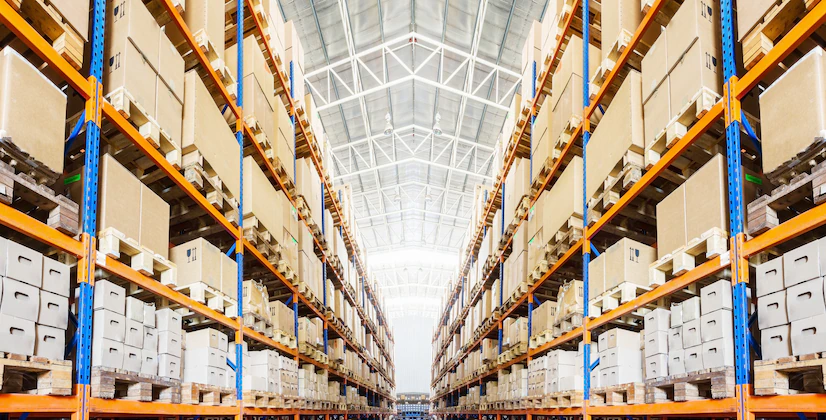

Running a warehouse can be a challenge. When even the smallest mistake occurs, it can send ripples through your entire supply chain.

To avoid this, you need to create a plan of action for how to improve your operations to increase overall efficiency.

Take a moment to look over these tips and put together a strategy that will keep your facility running the way that you intend.

What is Warehouse Operations?

Managing the warehouse is probably one of the most prominent aspects of maintaining a manufacturing and distribution venture. Without effective warehouse management operations, businesses might end up tanking.

But what are warehouse operations? Well, warehouse operations include processes like storing, packing, and managing inventory. All of this is done to understand the way a warehouse works.

Warehouse Operations Job Responsibilities

Managing a warehouse is definitely not a job for the fainthearted. It is a highly technical skill that needs special attention and understanding.

A warehouse manager is tasked with the job of assigning partners to manage the warehouse. The manager needs to have clarity, and an understanding of the different processes involved and the skills each employee possesses. All these pieces of information are crucial for effective warehouse management.

Apart from this, a warehouse manager also needs to make sure that the general cost of the process is down. Therefore, it is a highly complex job that requires long-sightedness and clarity.

Here are some of the most prominent warehouse operations job responsibilities that you must understand and explore:

- Operations Manager

- Supervisor

- Clerk

- Manager

- Worker

The designations might be different but the general process for warehouse management stays the same. The order trickles down from the Operations manager to the worker.

General Workflow

Warehouse operations are primarily focused on four different work processes. These add to the overall essence of the department. Here are some of the most prominent job processes that a warehouse operations manager needs to look at:

- Receiving

- Storing

- Picking

- Returns

These are the four principal or primary responsibilities that a warehouse operations team needs to look at. However, since the industry is expanding rapidly, these job processes can evolve or get automated for the sake of optimizing warehouse operations.

Implementing Technology

As we just pointed out, technology has become very crucial in the last few years. Therefore, understanding the overall essence of development is vital.

The whole organization can change itself with technological advancement. However, you must understand that with technology comes accessibility and other complexity.

Therefore, machine learning and AI can change the game, but overall reliability is still a prominent question on everyone’s mind.

Crucial Steps for Improving Your Warehouse Operations:

Want to improve your warehouse operation? Well, you need to follow the following tips and tricks. Remember that enhancing or scaling your warehouse operations is a nuanced job, to say the least. However, knowing what to do can certainly help you get ahead in this job, and that is what we are helping you with.

1. Scale Back on Inventory

In recent years, the concept of “lean” warehouses has become quite popular. Basically, the idea here is to only store what is absolutely necessary for your facility. Overcrowded or cluttered warehouses can greatly increase the chances of an accident happening.

What’s more, it can be difficult to find the product that is needed when the shelves are loaded with items. By adopting the lean method of storage, you can limit potential injuries and improve the overall efficiency of your facility.

2. Focus on Your Equipment

Functional machinery is required to keep a warehouse running smoothly. To assess whether your tech is performing the way it is meant to, you must conduct routine maintenance every so often. The forklift is a perfect example of an asset your business cannot afford to lose.

Check the lift every few months and take note of any signs of wear you come across. To avoid a total breakdown, find appropriate Nissan forklift parts you can use to replace worn pieces and reduce the odds of your tech failing you when you need it most.

3. Incentivize Your Staff

When your business starts to take on more clients, it tends to place heavier demands on the members of your team.

Instead of hiring additional workers, you may find it is more beneficial to incentivize existing staff. Offering bonuses and other financial rewards for going above and beyond each day can be the perfect way to increase the speed of operations while also taking proper care of your employees.

4. Pay Attention to the Supply Chain

Even when you are on top of the responsibilities of running your warehouse, there are problems that can appear due to no fault of your own. This is typically the case when there is a disruption to the supply chain.

Even the slightest setback with one of your vendors can cause major disruptions to the daily operations of your facility. Create a contingency plan that addresses how warehouse employees should respond to inbound delays.

By doing this, your team will know exactly how to respond when operations don’t follow the standard flow.

5. Analyze Performance Data

Finally, don’t forget what data can tell you about your operations. Take time to review records related to your warehouse’s performance during previous years. Analyze the information and attempt to pinpoint times when your company was the most efficient.

Dig deeper and determine which factors contributed to your success during these periods. How you analyze data and what you do with the information down the line will be unique to your facility, but the process itself can be invaluable to all warehouse operators.

Increasing the efficiency of your warehouse is not an overnight goal. To see the best results from your hard work, you need to give yourself ample time to review a few basic points and craft a strategy that addresses both your strengths and your weaknesses.

The Final Thought

In summation, you must understand that warehouse operations are a significant and valuable detail that businesses need to look after.

Otherwise, they might suffer grave consequences. Hence, if you are planning on entering this business landscape, you must be prepared to take this job role.

Thank you and have a great day ahead.

Additionals: