Key Benefits of Automated Storage and Retrieval System

by Abdul Aziz Mondal Business Published on: 23 February 2022 Last Updated on: 30 January 2026

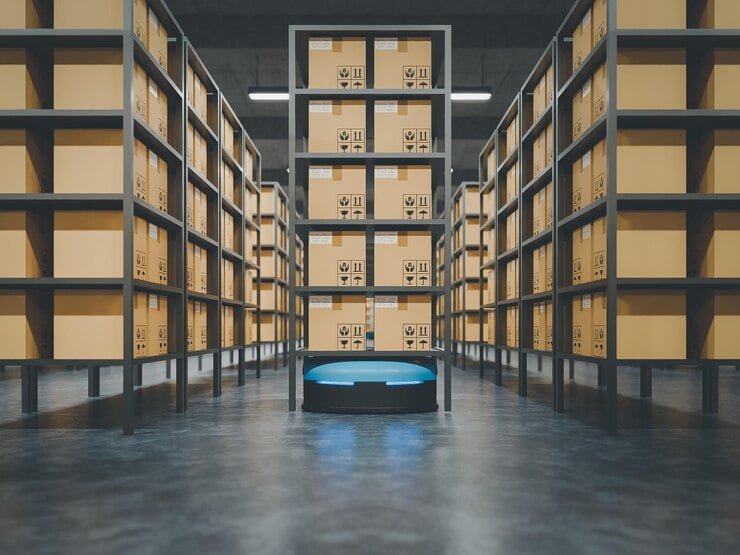

In the last few years, the scale of warehousing and packaging has increased drastically. Without the integration of technology, software, automation, and robotics it is practically impossible to efficiently run spaces that are over a million square feet!

We are talking about thousands of products, inventories, and systems. Manually running such a system can lead to compromises in time, delivery, service and also end up damaging the goods and products.

In this regard, Automated Storage and Retrieval Systems or AS/RS have emerged as leading solutions for distribution facilities. Think of a large business like Amazon and the kind of inventory it stores and processes every single day.

The slightest problems in one order can have a chain reaction that can offset the entire supply and logistics chain. There are hundreds and thousands of businesses that face the same set of challenges in their operations. An AS/RS system helps them in multiple ways.

In this article, we are going to shed light on some of the key benefits of automated storage and retrieval systems. However, before we get to the list of advantages, let us first look to offer a comprehensive definition of what an AS/RS system is.

Automated Storage and Retrieval Systems: Meaning and Definition

As the name suggests, an AS/RS system comprises a set of computer applications and software that command robotics and hardware processes. When you enter a command to locate a product, the software directs the hardware to identify where it is and retrieve the same to a loading or unloading area.

Big warehouses that have fifty feet shelves are now shifting to a more operations-friendly AS/RS process. With every footprint of a product being stored in the database, AS/RS systems enable the creation of a far more compact area of work. The robotics and automation work deftly through pallets and move inventory in a fast, safe and recorded manner.

The following are some important things that you should know about AS/RS solutions-

- These systems can handle different volumes of goods that are different in sizes, weights, and dimensions.

- AS/RS systems can work in different velocities. This means that you can increase or decrease the speed according to how comfortable humans are.

- The location, delivery points, and other data are stored in a centralized system. Reading this data can help the business to speed up operations and efficiency.

If you are currently looking for more information about AS/RS system, you can find it at https://www.gosrsi.com/raft-asrs-pallet-storage/

List of 7 Key Benefits of Automated Storage and Retrieval Systems (AS/RS)

1. Better Utilization Of Floor Space In The Warehouse Facility-

If you have ever been to a large warehouse or distribution center, you would have seen the tonnes of space that aisles eat up. The aisle space enables movement, but when you use an AS/RS system, you do not need humans or machinery like pallets and forklifts to move up and down the aisle. This means that you can better utilize the floor space in the warehouse.

2. More Storage Spaces To Place Larger Inventories, Goods, And Products-

Following from the first point, if you do not have aisles, you can convert the same to more storage spaces. This means that using an AS/RS system enables you to store more products in the same warehouse. You do not have to rent or buy a new space and set it up. All you need to do is use an AS/RS system and convert the large aisle spaces into storage. That’s all!

3. Decreased Manual Involvement And Requirements-

If you are automating your warehousing, you do not need to engage the services of too many humans. Businesses need to understand that manual work can result in mistakes, that cost time, money, and effort. Automation and tech integration means that you have far less human staff, salaries to pay, and lawsuits (in case of warehouse injuries) to contend with at any time.

4. Significant Reduction In Human Errors And Mistakes In The Logistics Process-

Every time a human being is involved with a specific process, there is a possibility of committing a mistake. By taking human beings out of the equation, businesses can improve efficiency and reduce human error. For example, picking is a significantly important process that can invite mistakes. It can delay processes and cost time, money, and credibility.

5. AS/RS Allows For Batch Picking To Speed Up Logistics Processes-

If you are familiar with warehousing operations, you know that one human picker usually caters to one individual order. Data points out that this can help in processing 50 orders in an hour. When AS/RS systems are used, you are looking at 50 orders in a minute! The system is fast, effective, and efficient. It allows for group or batch picking as against individual ones.

6. Integration With Inventory Management Systems For Greater Control-

For large warehouses, integration with their ERP and Inventory Management Systems (IMS) is very important. It helps them keep track of what’s coming in and going out. Using AS/RS boosts inventory management and helps the organization keep track and monitor all the goods and products. This helps in tracking missing goods that might have been misplaced.

7. Aids The Humans That Are Delivery Operators In Their Delivery-

The importance of human delivery operators cannot be underestimated. With an AS/RS system, they are able to receive packages at the optimal height, also referred to as the ‘Golden Zone’. This is the spot that is between the human being’s shoulders and knees. This is an important collection point that allows them to load the same with better accuracy and efficiency.

The Final Takeaway

As business organizations become more complex and the consumer demand for faster delivery increases, AS/RS solutions can help businesses cater in the best possible fashion. They are going to become one of the most significant assets for your warehouse. If you are a distribution facility that is looking to optimize delivery speed, increase volume and minimize human errors, then you should most definitely check out AS/RS systems. If you would like us to assist you in any way, please let us know in the comments below.

Read Also: