What You Need to Know About Automated Optical Inspection Systems and Their Applications?

by Mashum Mollah Business Security Systems Published on: 08 May 2017 Last Updated on: 25 June 2025

The demand for consumer-grade components is constantly increasing, driven by the rapid evolution of the electronics industry.

As consumer standards for devices ranging from simple calculators to the latest smartphones and other electronic devices continue to rise, companies in the electronics manufacturing industry are pressured not only to produce more components.

They are also aiming to ensure that the increased production does not compromise the quality of each product.

Automated optical inspection (AOI) systems have enabled manufacturers to meet the demand for both quality and quantity.

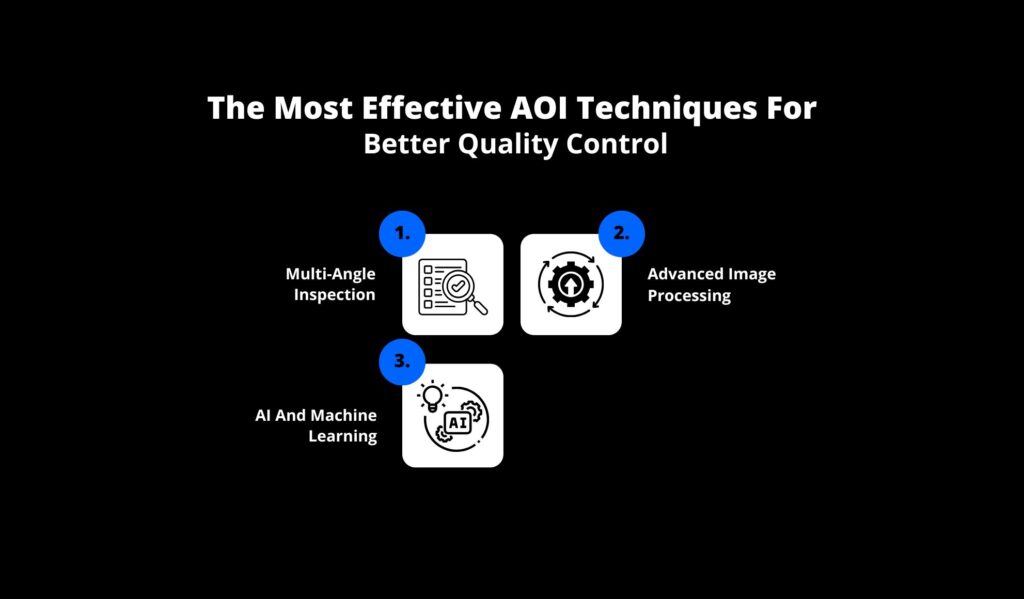

The Most Effective AOI Techniques For Better Quality Control

When you are running a business, it is necessary to keep the manufacturing quality control to achieve the utmost precision.

One missed defect, and it can easily lead to faulty products, customer returns, production headaches, and even wastage of money.

This is exactly where the AOI techniques come into play! These methods have been effective in conducting detection, assessment, and further verification of the manufacturing quality.

The aim is pretty simple: to keep things more efficient, consistent, and further cost-effective. The engineers use the following techniques to keep their quality control running in an effective way!

Multi-Angle Inspection

This is particularly about positioning the cameras at various angles during the inspection. This way, you can save a lot of time for inspection and further identify defects from separate perspectives.

Advanced Image Processing

In this process, you can monitor the manufacturing in real time, and that too with statistical alerts.

The image processing techniques also provide you with an automated response protocol, better and higher resolution protocols, along with high-resolution imaging.

AI And Machine Learning

Both AI and machine learning can be useful in analyzing data that you have inspected. The aim? Well, there can be a lot of defects that remain unidentified by the human inspectors.

The AI and machine learning take the initiative to predict potential failure before finalizing the manufacture.

When dealing with large-scale business production, these techniques can be highly beneficial. The techniques allow you to increase the factory efficiency and reduce the material as well as financial waste.

High-tech Eyes for High-tech Production

An automated optical inspection system comprises one or more cameras designed to inspect products, usually during various phases of the production process.

AOIs are commonly used to inspect the quality of printed circuit boards, transistors, and other components, as even the slightest defect can lead to serious problems.

The camera design is there to detect errors with margins of error normally indiscernible to human inspectors.

The cameras compare what they can scan to finely calibrated base values of variables required to pass production standards. Suppose any of the variables go beyond the acceptable limit.

In that case, the system sends a notification to stop the production and address all the defects to stop the replication in future batches.

Cameras used in AOI may have a limited field of view, and moving trays of PCBs to align with the cameras require a lot of space to give the tray enough room to move every piece into position. This is why today’s AOI systems move the cameras instead. A series of finely-tuned XYZ tables powered by powerful industry-grade components allow cameras to be repositioned both horizontally and vertically. As with the cameras themselves, these components can be programmed to move with extreme precision to make sure the cameras are always in the right place.

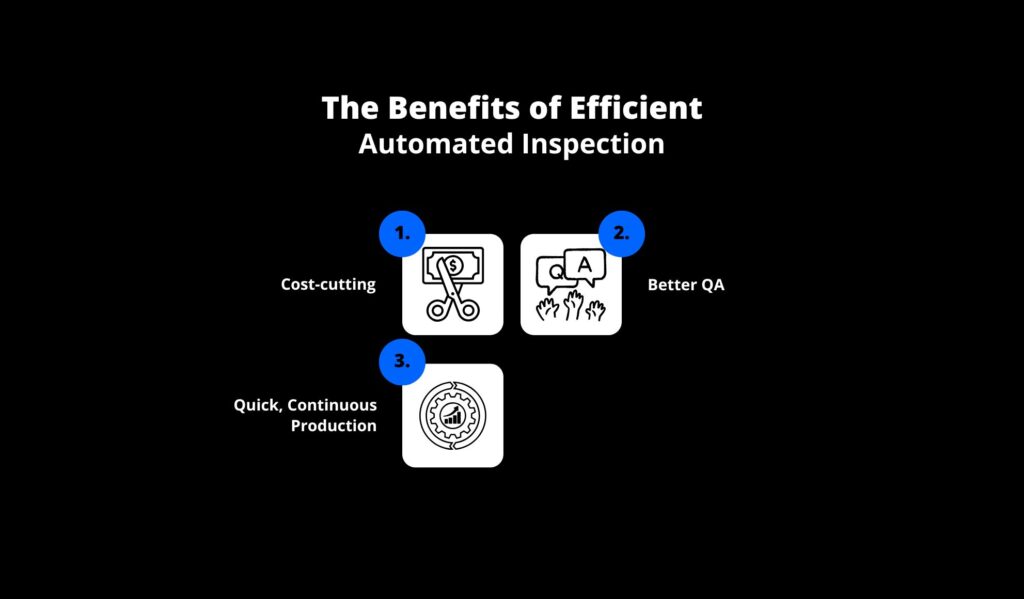

The Benefits of Efficient Automated Inspection

There’s no denying that AOI solutions have helped countless companies survive and even thrive in the electronics manufacturing industry. A closer a look at some of its benefits help shed light as to why businesses of every scale and size should prioritize the integration of AOI in their production process.

Cost-cutting – Resources required to address problems late during the production process can easily translate to huge losses. This is even worse if a batch of defects slips past inspection and forces a company to issue product recalls later on. Because an AOI system can check for defects even at the earliest parts of the production process, companies have multiple chances of detecting defects at stages where fixing them is relatively cheaper.

Better QA – As with any automated system, one of the biggest advantages of AOIs over manual inspections is the greater degree of precision when checking for problems. In contrast, manual inspections are prone to missing out on defects that would’ve been obvious under a camera.

Quick, Continuous Production – AOI systems can be programmed to check batches of products at a much faster rate than what an entire team of human inspectors would be able to handle. Also, AOI systems experience very little downtime, thanks to industry-grade parts designed to operate non-stop. In case something goes wrong with an AOI system, parts can quickly be replaced.

With so many benefits they can provide, it’s surprising that AOI systems are still mainly used for checking the quality of PCBs and other electronic components. However, many are hoping that it’s only a matter of time before the technology is adopted by businesses in other industries. With the development of more efficient, versatile, and affordable systems, AOI may soon become the norm in quality assurance for anything that involves manufacturing.

How Can Businesses Harness The Power Of AOI?

The AOI, or Automated Optical Inspection, systems are crucial for various industries. It can significantly contribute to maintaining the overall standard of quality.

Among all the other things, the AOI systems are specifically designed to inspect the bare semiconductor wafers and devices. This can further help to ensure high-quality manufacturing.

This early detection of the defects can help speed up the production process. Moreover, you can easily reduce waste while improving the product quality.

Read Also: