Selecting Contract EMS Providers

by Abdul Aziz Mondal Technology Published on: 29 September 2020 Last Updated on: 30 January 2026

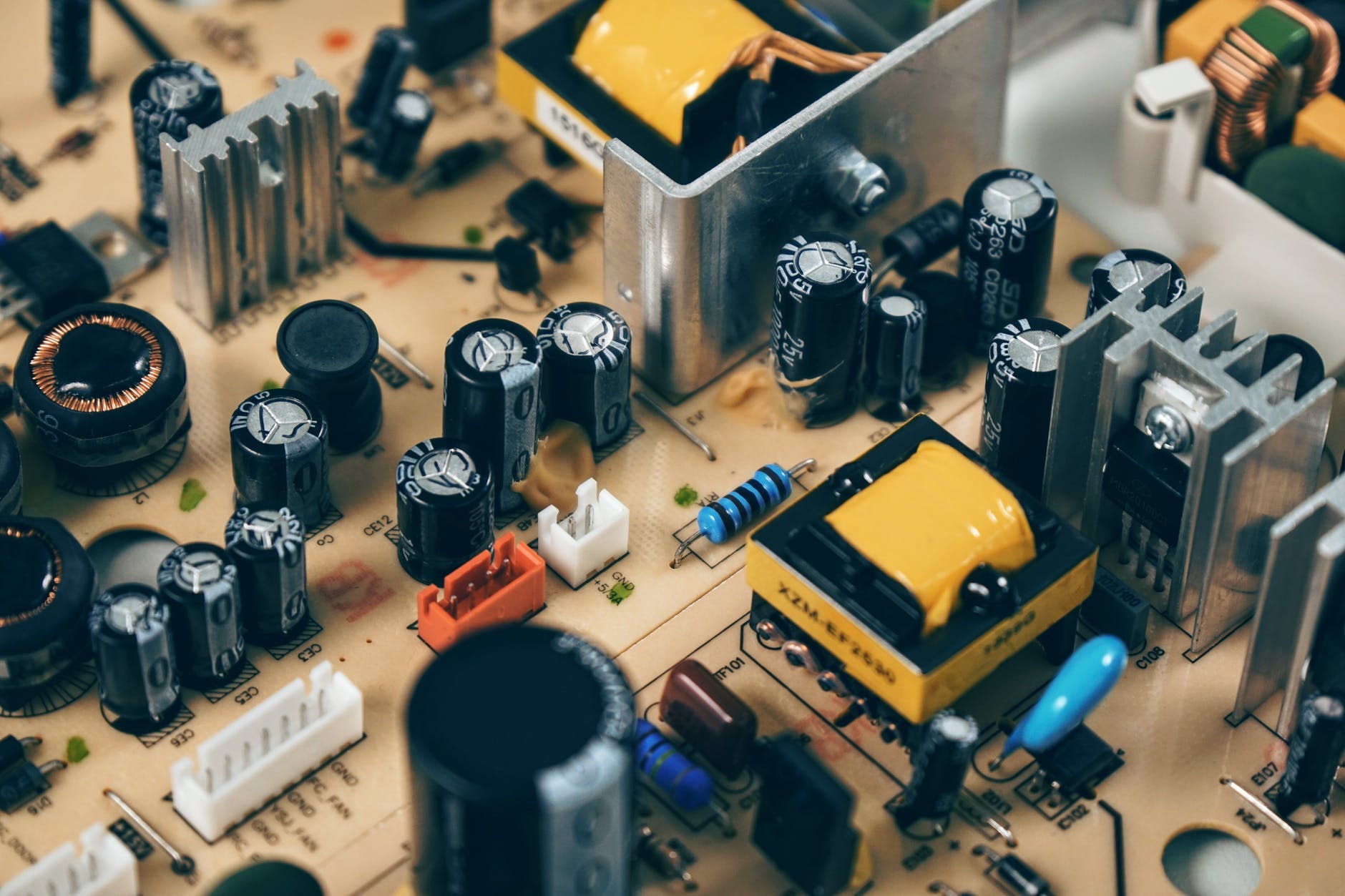

What are the electronics manufacturing services? Electronics manufacturing services (EMS) are companies that manufacture, test, distribute, provide, and repair services for electronic components and assemblies for original equipment manufacturers. The concept is also referred to as Electronic Contract Manufacturing.

EMS nowadays are also valuable business partners providing support, maintenance of the services they manufacture. Because the electronics industry is growing rapidly and developing fast, EMS has become an important part of many businesses in the world. Finding a suitable contract manufacturer can be a hard nut to crack, with a long list of criteria to consider before making the right decision.

Outsourcing EMS

Is outsourcing EMS the best way to do this business? The answer is yes. Outsourcing is not only the most cost-effective method of cooperation with a manufacturing partner, but we also need to remember that the process of assembling integrated printed circuit devices is very complex and involves preparing a proper production line and a team of experts who are familiar with the use and maintenance of the automated systems of the production line. A company providing EMS is able to reorganize a production line in a flash, choose qualified staff for the task as well as to conduct the assembly of contractual electronics. It is not hard to conclude that setting up the complete production line and finding proper employees is costly, time-consuming, and difficult. It may cause delays in production and loss of quality in the end, so eventually, the product may not stand up to the competition.

How to find and outsource the best EMS provider?

A suitable EMS provider has a cutting-edge technical base and experts of engineering support in their offer. The technical base should be able to execute highly complex SMT assembly. The production line should be flexible enough to rearrange quickly according to the customer`s needs. A top-notch EMS provider is expected to undergo inspections and testing regarding the safety of services and quality certificates at any time. The engineering support should be present at every stage of project realization-from early prototyping to production, post-production, and eventually product decline. When it comes to the mass production environment, it is never the same as a small production batch in a lab. The best EMS company knows how to implement NPI services in the process of product manufacture. Also, while selecting your EMS partner, it is advisable to organize a meeting their Procurement and Supply Chain team to get familiar with their vision, knowledge, and competences regarding the markets, as they will be your future support team working on optimizing your costs and improving your lead times for the successful project completion.

Going smart is very important. Choosing an EMS company with smart solutions in their factories will greatly contribute to the success of your project. Another issue is system integration. Your product is designed, manufactured, tested, and shipped in one ongoing process.

Read Also: