IQF Chicken Benefits | How Does it Compare to Others?

by Ankita Tripathy Business Published on: 09 May 2022 Last Updated on: 22 November 2024

Individual Quick-Freezing (IQF) is a method of freezing food, where the individual pieces of the food product are kept separate, even after the freezing process. The result is more convenient, affordable, and of higher quality than many products achieved through alternative freezing means.

IQF meat is frozen quickly, keeping its high quality, as well as excellent taste. Covering the growing niche of those looking for high-quality, high-nutrient-value frozen meat, IQF Poultry provides a premium-grade solution.

Worldwide meat consumption is predicted to grow, as a growing percentage of the world’s middle class becomes more interested in affordable, convenient, yet qualitative frozen meat solutions. As high-quality, high-food safety, sustainable solutions become the norm, there’s only one freezing approach that can keep up with the demand: IQF.

Meat-based foods are a crucial element of any restaurant or diner. Working with blocks of frozen meat is more difficult than the simplicity of individually quick-frozen meat, which comes already separated into pieces for easy use in food preparation. There’s a strong demand for IQF products containing meat.

What is IQF chicken and how does it compare with other types?

IQF chicken are flash-frozen chicken pieces that make it easy to thaw and portion out. The IQF technique is also used for vegetables and fruits.

IQF chicken has become a popular choice for household and fast-food restaurants due to its quality and convenience. This is what makes it one of the most used frozen chickens out there. This technique makes the chicken ideal for single-serving or batch cooking. Because IQF chicken is a flash feast it preserves its texture taste and nutritional value. The procedure also ensures the chicken retains moisture better than standard freezing methods which prevents the meat from becoming dry and tough.

Moreover, the IQF packaging prevents chicken pieces from sticking together which reduces the likelihood of throwing out excess chicken if you only need a small portion.

In comparison to fresh chicken, IQF chicken has a longer shelf life. Moreover, IQF chicken retains nutrients despite lasting for a long time. This is not offered by normal for fresh chicken as they have to be used immediately after buying.

Unless a dish requires fresh chicken IQF can offer grade flexibility without compromising the quality.

In comparison to bulk frozen chicken IQF chicken does not stick together and is present as pieces. As bulk frozen chicken is usually frozen as a whole or in larger portions it requires thawing the entire package before cooking. This leads to a lot of waste if you don’t want to use the whole chicken.

IQF chicken allows for easier portioning and makes it more practical for various male sizes. IQ of chicken tends to retain moisture better than the other option.

Lastly IQF chicken is more nutritious than precooked or breaded chicken. Unlike letter IQF chicken is free of preservatives and sodium. While breaded chicken may be convenient it does not offer the versatility or health benefits of IQF chicken.

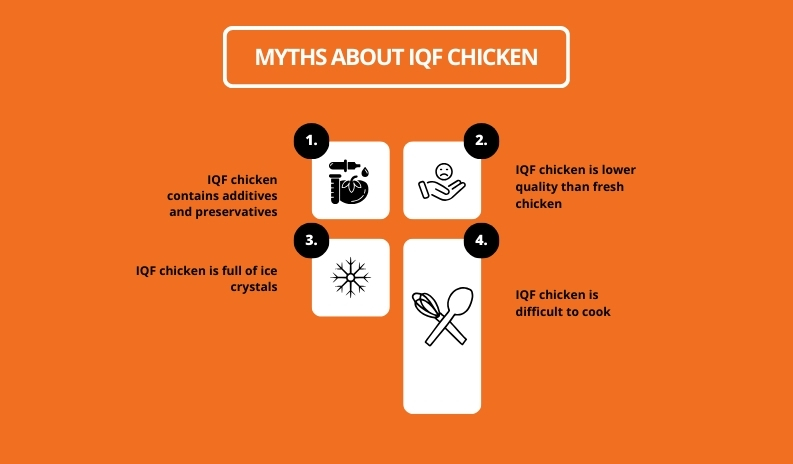

Myths About IQF Chicken

- IQF chicken contains additives and preservatives: The fact of the matter is that IQF chicken has pure chicken without additives. The quick-freezing process preserves freshness naturally and eliminates the need for preservatives. However, ensure you check labels for extra ingredients.

- IQF chicken is lower quality than fresh chicken: IQ of technology helps preserve the quality of chicken by freezing it at its best freshness. The texture, nutrients, s and flavor are well preserved and make IQF chicken better in quality in comparison to fresh chicken provided it is handled and stored properly.

- IQF chicken is full of ice crystals: IQF chicken minimizes ice crystal formation as each piece is flash-frozen individually. The quick-freezing process prevents ice crystals from forming which is seen in slow bulk freezing processes.

- IQF chicken is difficult to cook: In contrast, IQF chicken is comparatively easy to cook as it can be thawed quickly and in small portions as per requirement. Many recipes allow cooking directly from frozen chicken which makes it convenient for flexible and fast meal prep.

Checkout Benefits of Choosing IQF Chicken and Poultry

When you choose to buy and cook from IQF chicken and poultry you read the following benefits:

1. Innovative technology

Despite IQF flash-freezing being around since the 60s, when the freezing tray freezer was first introduced, individual elements of IQF freezing have been continuously improved over the years.

Enterprises like Octofrost have spearheaded the innovation, by improving efficiency, yield, product quality, and, perhaps even more importantly, food safety.

The transportation belt has been a staple of this type of meat processing technology, improving on the first design of fluidized beds for food transportation within the freezer. The stainless-steel belts came with their challenges, where cleaning and product quality became more difficult, as the belt would sometimes leave belt marks on softer product surfaces.

Further improvements introduced the plastic IQF belt, reducing the size of the gaps between links and improving results considerably. Again, the solution was imperfect, as the parts that linked the belt together took up too much space, reducing yield. The biggest challenge with conveyor belts remained difficulties in cleaning and ensuring food safety.

The newest addition to the industry was done by OctoFrost 25 years ago with their perforated bedplate design, replacing belts entirely. The product is patented and therefore unique, moving the product by asymmetric movements of the bedplate and static friction between the plate and the product.

Practically 100% of the bedplate’s surface contributes to the fluidization, creating ideal circumstances for high yield. That makes it easier than ever to process considerable amounts of poultry without worrying about performance.

2. Food safety

The previously discussed technological innovations come with an entirely new, exciting consequence: maintenance and food safety have become much easier. A critical element of any freezing process is ensuring no contamination takes place. When working with meat, this becomes even more important.

Fortunately, the bedplate design makes it quite simple to perform cleaning, all while continuing the freezing process as normal. The bedplate that needs cleaning can be simply extracted, replaced with a fresh bedplate, and washed outside the freezer.

This ensures food safety that is ahead of current industry standards, future-proofing your business, and ensuring that the premium-grade quality of your product will remain so.

Beyond that, the tunnel freezers themselves can be cleaned simply, thanks to their design. The easy-to-clean design allows for improved food safety and makes it easier to perform, motivating it.

3. Better results

Compared to other freezing processes, IQF freezing produces a result that is of better quality. The reason for that lies in the process itself: IQF. Extremely fast freezing is an IQF staple, leading to a phenomenon that prevents large ice crystal formation.

These crystals could harm the product and reduce its quality. While slower frozen food processing methods allow this to happen, IQF avoids this issue thanks to the extremely fast processing speed.

During defrosting, a noticeable amount of juice will leak from the product caused by the damage of this large ice crystal formation. By avoiding this potentially damaging effect, the cells of the product remain unharmed, and the frozen product quality increases when compared to other freezing methods.

4. Unique benefits

Beyond the previously discussed improvements and benefits, IQF supplies unique benefits. The portion control afforded to you is extraordinarily high, as individual pieces of the poultry can be used as you see fit.

An added benefit is the low thawing time. When marketing to fast-food chains especially, this can be an important deciding point. Time is money, and saving time means saving money for the beneficiaries of your frozen product, increasing its value even further.

Sustainability can be a key factor to consider, and IQF’s approach of separating the product into pieces contributes to it. As beneficiaries of the product can thaw as much as they need, this prevents unused parts from being thrown out or underutilized.

Smaller pieces of the frozen product also represent advantages for product presentation and form.

5. Product advantages

For the frozen product itself, IQF frozen chicken meat will preserve its natural appearance and most of the natural vitamins that make it so nutritious. The product stays appetizing when frozen and thawed, which methods like cold storage freezing, for instance, do not guarantee.

Fewer nutrients are lost thanks to the speed with which IQF processing happens, resulting in a product that will have more to contribute to the consumer’s health.

The high food safety ratings of Octofrost’s bedplate technology are transferred onto the product, making your poultry some of the most food-safe across the industry.

6. Technological supremacy

With high yield, excellent engineering, and design, as well as energy efficiency ratings among the leading IQF technology providers, it’s difficult to imagine other approaches as competitive.

Low dehydration, no lump formation, and efficient product separation are all guaranteed, but when combined with the energy savings, it’s possible to fine-tune your processing line to extract the most possible utility, while reducing costs and lessening product waste.

The tunnel freezer supplies excellent energy efficiency, as each fan can be adjusted, perfect for processing lower volumes, ensuring savings of up to 30% when using leading IQF tunnels on the market.

Thawing It Up!

IQF chicken is a versatile high-quality quality and convenient option for anyone looking to preserve freshness without sacrificing flexibility. The flash-freezing process helps keep the chicken nutrient-rich by preventing combinations with bulk frozen meat. As the chicken pieces are individually frozen it is easier to cook with smaller portions without wasting excess.

The article attempts to bust a few myths about IQF and helps understand the benefits that make it a smart choice for homes and restaurants.

Read Also: