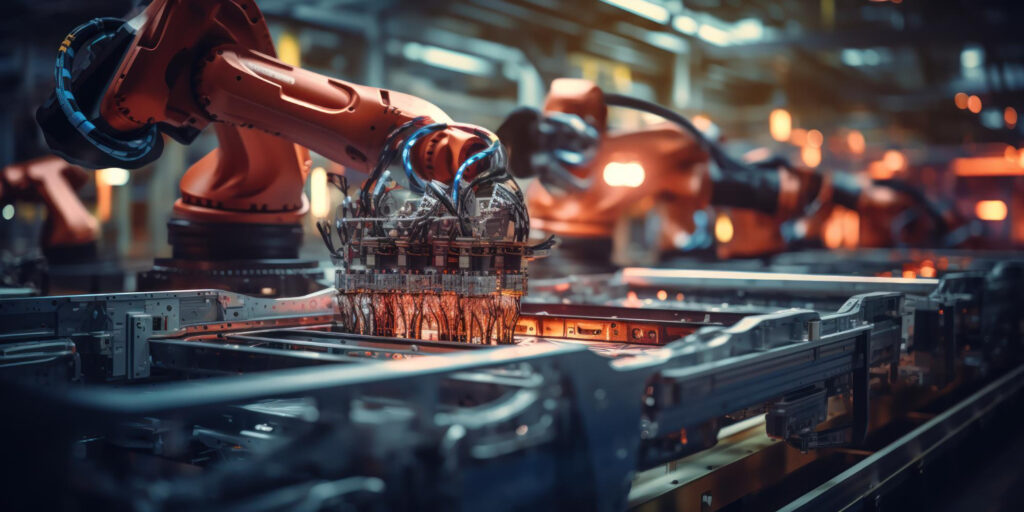

Embracing Automation: How Robotics Is Changing Sheet Metal Fabrication

by Arnab Dey Technology 02 May 2025

The industrial landscape has come a long way from where they were.

The landscape has gradually evolved from steam-powered megastructure churning products at a snail-ish pace to an automation and robotics-driven industry where manufacturing time has been reduced to mere minutes.

Overall, the world has transformed itself, and so have the expectations of the consumers and manufacturers. Now, everything is automated and is done at a lightning pace. Gone are the days of manual-driven industry.

This article will examine how robotics is changing sheet metal fabrication. We will see how sheet metal companies use robotics and automation to double their production, increase consumption, and cut production time in half.

Overview Of Automation In Metal Fabrication

Human beings have been working with metals forever. Metal is one of the oldest working elements, and it is used for various purposes, such as manufacturing fastening materials, weaponry, and buildings.

However, anybody who has worked with metal will tell you it is not the easiest material. Metalworking takes time and expertise. Therefore, metalwork used to often come with a heavy price tag. This also compelled people to start using plastic as a working element.

Automation in metal fabrication minimises the legwork and makes the project easier to manage. Therefore, it can make the production process more streamlined and organic.

Why Is Automation Gaining Ground?

Automation is one of the most important trends in the manufacturing industry. To understand how robotics is changing sheet metal fabrication, you must understand the reasons that made it so big.

This section will list some key reasons that have catalyzed automation in the metal sheet fabrication industry. However, the industry is evolving at a meteoric pace, so the reasons can also evolve. Hence, approach the section with tempered expectations.

Improved Precision

The metal sheet industry demands precision. In this industry, a millimeter can make a world of difference. One small error or loss of precision can render a whole project useless.

This is where automation or robotics comes into play. Automated cutting and tempering approach the project with a level of precision that is humanly impossible.

Enhanced Efficiency

Working with hot metals and equipment can be taxing for a human being. After working fr a while, that person would have to take breaks to rejuvenate. However, a robot will not face such problems.

A robot can do double the amount of work a human worker could, but at a shorter span of time and without any breaks. Therefore, increasing the general level of efficiency.

IoT Connecticity

The Internet is an important tool that can be used across many different industries. Internet connectivity allows machines to interact with each other.

Not only that, but it also makes threat and breakdown detection easier. As a result, it improves the workability of machines and saves extra money that maintenance might demand.

AI Functionality

Artificial intelligence might not allow robots to revolt like the Sci-Fi movies have taught us. However, it is useful nonetheless. AI will enable machines to assess and make basic decisions that make the process easier and more organic.

This also allows the project to have a basic sense of flexibility, all of which enhances the productivity and functionality of the metal manufacturing industry.

Better Safety

Metalworking is not only tedious but also quite dangerous. It comes with some inherent risks and dangers. However, robots nullify these problems. Unlike humans, robots cannot get hurt or feel physical pain.

This makes them perfect for completing complicated projects with a high risk percentage. As a result, they minimize the risk of an accident that can halt the entire production chain.

Ease Of Implementation

Implementing robots is a cost-intensive process. However, this is untrue in the present context. Implementing robots in any industry is no longer cost-intensive.

Most companies now offer easier and more streamlined implementation options. Therefore, modern metalworking companies do not need to bother with implementation problems.

How Can Automation Enhance The Steel Manufacturing Industry & Enhance Business

Now that you know how robotics is changing the sheet metal fabrication industry, let us examine some more detailed and technical reasons you need to understand if you want to be a metal entrepreneur.

Quality Control

Projects that use Robotics at their core tend to save money on quality control. Robotic-enabled manufacturing reduces the scope of quality control.

Therefore, companies implementing AI and robotics in their foray can save money and allocate the QC funds to places where they can work better.

Operational Cost

Automated labour or robotics can bring down the overall operational cost. However, operational cost is an umbrella term. In other words, many different costs fall under the shade of the operational cost.

Robot-enabled manufacturing brings that cost down by reducing the scope of human intervention. This brings the cost and increases the profitability of a project.

Increased Production Flexibility

Production flexibility is an important detail. It allows a production line to handle multiple projects simultaneously.

An automated production line can handle this the best without any hassle, making it perfect in many scenarios where the project demands flexibility.

Optimizing Material Usage

Automated systems are much better at optimizing their material usage. In other words, the more efficient working of the robotic manufacturing line improves material usage. Production lines with AI tend to leave a lower level of waste material, which enhances metal usage and reduces the cost of raw materials.

Enhancing Competitiveness

Businesses that are actively adopting robotics and automation are making themselves future-proof. In a few years, AI and automation will become a standard practice. Therefore, if you miss the chance now, you can easily become obsolete and lose out on business in the long run.

What Can The Future Be?

In summary, robotics is changing the sheet metal fabrication industry. AI and robotics are making the industry more in sync with tomorrow’s expectations.

Therefore, if you want to dip your feet in the metalwork industry, you must consider robotics to enhance your production capabilities and bring the cost down simultaneously. Therefore, take your time, but do consider the pointers mentioned here.

Let us know if you liked this content, and follow us for more.

Read Also: